Technical Difficulties and Countermeasures of Drilling ofΦ118mm Sidetracking Horizontal Well in Changqing Oilfield

AI Lei; XU Wenhao; LIU Hanbin; GAO Yunwen; ZHAO Wei

[a] Oil and Gas Technology Research Institute, Changqing Oilfield Company, PetroChina, Xi'an, China.

[b] Drilling Technology Research Institute of Sinopec Shengli Petroleum Engineering Co., Ltd., Dongying, Shandong, China.

Abstract The boreholes of the horizontal side-drilled wells with casing windows in Changqing Oilfield are all Φ118mm. Difficulties in the construction of small-hole drilling include high landing risk in the horizontal section, difficulty in slope prediction and trajectory control, and limited extension capacity of small wellbore. By optimizing the trajectory of the borehole, designing the trajectory adjustment section before the horizontal landing well, and introducing the equilibrium trend angle method to predict the slope of the directional tool, we improved the trajectory control ability; by calculating the stability of the drill string and the loss of cyclic pressure and analyzing the displacement extension ability, we optimized drill string selection and formed a precise trajectory control method based on sidetrack horizontal well trajectory optimization. Based on the analysis of displacement and extension ability, a non-standard drill pipe with a large diameter of 88.9mm and a small hydrophthalmia was selected. It is considered that the technical countermeasures and suggestions in this paper are of good reference and guiding significance for the development of sidetracked horizontal wells drilling in Changqing Oilfield.

Key words: Sidetrack horizontal well; Displacement extension ability; Trajectory optimization

As an effective means of tapping and adjusting and recovering production of stoppages in old areas, sidetracked horizontal wells drilling in Changqing Oilfield, with the application of staged fracturing completion technology,can increase the productivity of low-pressure, low-permeability, and low-abundance oil and gas reservoirs in conjunction. At present, the main application blocks include the Sugali gas field and the Ansai low-permeability oil field. For the Changbei block, Zizhou gas field, Yulin gas field and other oil and gas fields with potential for development, demonstration work has been carried out successively (Xu & Ding, 2012; Pan, et al, 2019).Because the side-drilled horizontal wells in each block of Changqing Oilfield are implemented with side-drilled windows in a Φ139.7mm casing and because the boreholes of open-hole sections are all Φ118mm, the difficulties in the construction of small hole wells are mainly the high landing risk in the horizontal section, difficulties in controlling slope prediction and trajectory and the low drilling speed of small boreholes. Aiming at these difficulties, a research is carried out on the optimization of the orbital profile and the analysis of the displacement extension ability of horizontal wells, and put forward targeted technical countermeasures.

1. DIFFICULTIES IN DRILLING TECHNIQUE

a) Great difficulties in controlling the wellbore trajectory, and the high risk of landing in the horizontal section.

The directional tool build slope is highly sensitive to changes in underlying and drilling parameters. The range of build slope change is large. And the prediction accuracy is difficult to be guaranteed. the accuracy of the trajectory control into the oil and gas layer is not considered while designing, and the landing risk in the horizontal section is high

b) Insufficient performance of small-sized drilling tools and limited displacement and extension capabilities

Conventional side-drilled horizontal wells use the Φ73mm API standard drilling pipe. The drilling tool has weak rigidity, low stability, has difficulty in drilling pressure transmission, and has low sliding drilling efficiency. The drill pipe hydrophthalmias is small, the circulating pump pressure is high, and in construction, the reached 20-27Mpa.Since its restricted, weak hydraulic capacity, horizontal section extension ability and wellbore cleaning was affected (Li, 2019); the low mechanical strength of drill pipe make fatigue failure accidents of drilling tools easy to happen, and thus increase auxiliary operation time

2. BOREHOLE TRAJECTORY OPTIMIZATION

When there is a large deviation between the predicted depth of the reservoir and the actual drilling depth, the trajectory adjustment of the landing well section is lagging, and the landing safety risk is high. Through the optimization of the orbital profile, a large-slope stable-slope section is designed before the landing well section to improve the trajectory adjustment margin. Before drilling to the predicted depth of the reservoir, keep drilling at a steep slope and at a stable slope. If the reservoir is encountered when drilling ahead of time, enough well sections can be directionally increased to a suitable angle. If the actual drilling depth lags behind the reservoir, we will continue to maintain the current stable inclination angle and continue to explore the reservoir. This conservatively controlled trajectory optimization can improve the accuracy of the trajectory control of the landing well section,avoid the horizontal section loss caused by the lag of the trajectory control, and avoid the risk of the target area.During the landing control process in the horizontal section, the tilt measurement must be encrypted and we must adjust in a timely manner to ensure an appropriate stable angle.

The well Su 10-39-21CH uses a double-increasing profile with a slope rate of 6.5 ° / 30m and 5.8 ° / 30m. The well's stable slope section has an inclination angle of 45 °. Taking this well as an example, in accordance with the above-mentioned optimization principles, a stable slope of 84.6 ° was designed before landing to reduce the landing risk of horizontal wells.

Table 1 Section of the original shaft structure

Table 2 Optimized wellbore profile

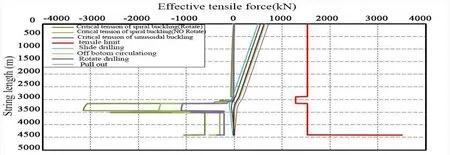

We use Landmark WellPlan software to simulate friction torque and drill string stability of the two sections before and after optimization. The software simulation conditions are as follows: The readings of the drilling fluid rotational viscometer with the models of 600, 300, and 3 revolutions are 56, 36, and 4, respectively. The drilling fluid density is 1.2g / cm3; the drill string structure is "Φ118mm drill bit + Φ95mm screw + Φ73mm drill rod(915m) + Φ73mm weighted drill rod (270m) + Φ73mm drill rod"; the friction coefficient in the casing is 0.25; the drilling pressure is 40 ~ 60kN, the speed is 60 ~ 70r / min. The calculation result of effective tension is shown in Figure 1. The tension curve of the sliding drill intersects with the minimum tension curve of sinusoidal buckling near the drill string length of 3000m, which indicates that during the sliding drilling, sinusoidal buckling will occur in this segment of the drill string. We convert the calculation results of effective tension in different working conditions into friction resistance, and get the buckling condition and friction torque. The calculation results are shown in Table 3. The calculation results show that the friction torques of the two sections under sliding drilling conditions are basically the same. In addition, a slight sinusoidal buckling phenomenon (sinusoidal buckling well length less than 200m) also appeared near the sidetracking point. The use of the optimized borehole track profile will not increase the construction risk.

Figure 1: Diagram of the effective tension of the optimized profile

Table 3 Comparison and analysis of friction torque

3. STRUCTURE OPTIMIZATION OF DRILL STRING

The drill pipe used in the horizontal well construction of Changqing Oil and Gas Field is Φ73mm. The drill string used is weak and therefore prone to buckling instability. And the drill string hydrophthalmia and annulus clearance are small, and the cyclic pressure loss is high. Drill string stability and cyclic pressure loss have become the main limiting factors for sidetrack horizontal well displacement extension. We still take Su 10-39-21CH as an example. Using the same simulation conditions above, and setting the drilling displacement to 6-12 L / s, we calculated the maximum displacement extension ability of the horizontal section under the constraints of drill string stability and cyclic pressure loss.

3.1 Analysis of Drill String Stability

We calculated the relationship between the stability of the drill string and the displacement of the horizontal section under different friction coefficients. The calculation results (see Table 4) show that when the naked eye friction coefficient is lower than 0.3, 0.35, 0.4, the extension distance of the horizontal section displacement will reach 900m, 800m, 600m. When the coefficient of friction is greater than 0.35 and the displacement extends to 800m, helical buckling will occur when the pipe string is lowering. In this case, there will be a greater risk when continue to lower the pipe. As the coefficient of friction increases, the condition of the wellbore will continue to deteriorate. If the friction coefficient is greater than 0.4, the displacement extension will reach 600m. In this case,the drill will undergo helical buckling. At this time, if we continue to drill, there will be greater security risks. If the displacement extension reaches 900m, the torque of the drilling tool in the inclined section will exceed the upper buckling torque. If construction is carried out in this case, the drilling tool connection failure will easily occur. The relationship between torque and well depth is shown in Figure 3.

Table 4 Buckling state of drill string of different displacements

Figure 3: Drill string torque at horizontal displacement of 900m and friction coefficient of 0.4

3.2 Analysis of Circulating Pump Consumption

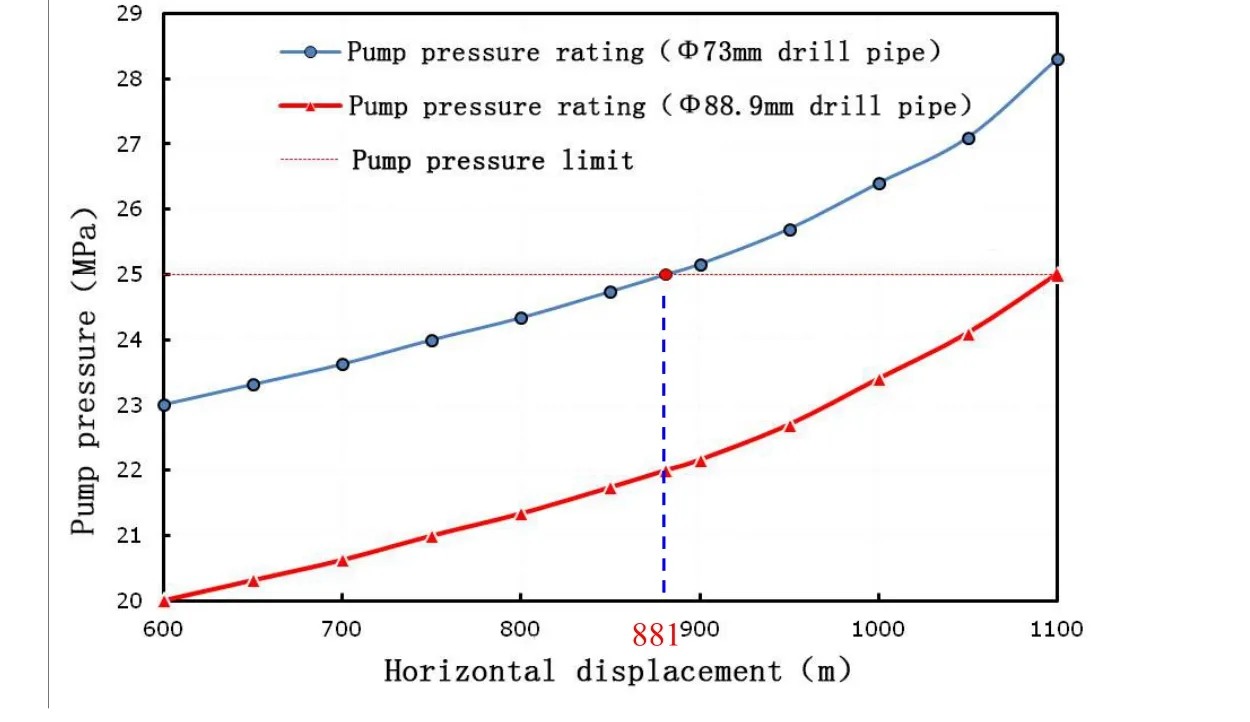

We analyzed the hydraulic elongation ability by calculating the annular air pressure consumption under different displacements based on the evaluation of the wellbore cleaning ability. Considering the sealing and pressure resistance of the ground manifolds and connectors, in order to ensure safe drilling, long-term high pump pressure operations must be avoided. The upper limit of the pump pressure is designed to 25Mpa. According to the wellbore cleaning theory, the height of the cuttings bed should be less than 10% of the diameter of the wellbore,and the concentration of the cuttings bed should be less than 5% of the total concentration. The reasonable minimum displacement determined by calculation is 8L / s. With this displacement, the pump pressure exceeds 25 MPa when the displacement extends to 881 m. This depth value is the maximum hydraulic extension distance.The calculation results of different displacement pump pressures are shown in Figure 4.

Figure 4: Calculation results of different displacement pump pressures

During the drilling process, the construction displacement should meet the needs of wellbore cleaning(minimum displacement ≥8 L / s). Problems such as instability of the borehole wall and unsatisfactory sand carrying due to engineering or drilling fluids will lead to increased circulation pressure loss and construction displacement of only 6-7 L / s. Taking Su 36-6-9CH well as an example, during the construction of the horizontal section, the pump pressure has reached 28 MPa with a displacement of 6.5 L / s, which severely limits the full play of the hydraulic capacity.

3.3 Optimization of Φ88.9mm Non-Standard Drilling Tools

Based on the analysis of drill string stability and cyclic pressure loss, in order to improve the stability and hydraulic performance of the drill string, we carried out the optimization of small size drilling tools. Limited by Φ139.7mm casing and Φ118mm side borehole, the outer diameter of the drill pipe coupling must be less than Φ110mm. Drawing on the domestic small hole drilling tool supporting experience, we use Φ88.9mm small coupling big hydrophthalmia non-standard drill pipe to replace Φ73mm API standard drill pipe in the whole well.The outer diameter of non-standard drill pipe coupling is Φ108mm. Table 5 shows the drilling parameters.

The application of non-standard drill pipe with a size of Φ88.9mm can effectively improve the strength, stability and hydraulic performance of the drill string, and improve the drilling efficiency. If this kind of drill pipe is selected when the naked eye friction coefficient is not greater than 0.3, the maximum displacement of the horizontal section of the drill string helix buckling will not reach 1200m. Compared with the original drill assembly displacement, it increased by 300m. Under the condition of reasonable minimum displacement, the hydraulic extension capacity reaches 1100m (see Figure 4), which increases the displacement by 235m relative to the original drill assembly. Comprehensive consideration of drill string buckling and pump pressure limitations,and under the condition of controlling the naked eye friction coefficient not greater than 0.3, the use of Φ88.9mm non-standard drilling tools can increase the displacement to 1100m, which improves the drilling capacity of Φ118mm sidetrack horizontal wells.

Table 5 Performance parameters of Φ88.9 mm non-standard drill pipe

CONCLUSION

(1) The variation of the wellbore slope is highly sensitive to formation and drilling parameters. By optimizing the orbital profile and increasing the slope-stabilizing section before the landing well section, the risk of landing a small wellbore can be reduced and the accuracy of trajectory control can be improved.

(2) By adopting a small-diameter large-waterhole non-standard drill pipe with a diameter of 88.9mm, the drilling efficiency of a side-track horizontal well with a diameter of 118mm can be effectively improved in Changqing Oilfield.

Advances in Petroleum Exploration and Development2019年2期

Advances in Petroleum Exploration and Development2019年2期

- Advances in Petroleum Exploration and Development的其它文章

- Description of Shale Pore Fracture Structure Based on Multi-Fractal Theory

- Comparative Analysis of Abnormal Pore Pressure Prediction Models for Niger Delta Oil and Gas Fields Development

- Development of a New Model for Leak Detection in Pipelines

- Optimizing Production in Brown Fields Using Re-Entry Horizontal Wells

- Economic Analysis of Low Salinity Polymer Flooding Potential in the Niger Delta Oil Fields

- Using Shallow Platform Drilling Technology to Tap the Reserves of the Below Constructed Area of Fuyu Oilfield:Taking Chengping Block 12 as an Example