Coalbursts in China: Theory,practice and management

Yishan Pan ,Yimin Song ,Hao Luo ,Yonghui Xiao

a Institute of Disaster Rock Mechanics,Liaoning University,Shenyang,110036,China

b School of Civil Engineering,North China University of Technology,Beijing,100144,China

c College of Computer Science,Liaoning University,Shenyang,110036,China

d School of Physics,Liaoning University,Shenyang,110036,China

Keywords: Coalbursts Rockbursts Dynamic disaster Energy-absorbing support Monitoring and early warning

ABSTRACT Coalburst is one of the most serious disasters that threaten the safe production of coal mines,and this disaster is particularly serious in China.This paper presents an overview of coalbursts in China since 1980s.From the "stress and energy" and "regional and local" perspectives,the achievements in the theory,practice and management of coalbursts in China are systematically summarized.A theoretical system of coalbursts has been formed to reveal the deformational behavior of coalbursts and explain the mechanism of coalbursts.The occurrence conditions of coalbursts are put forward and the critical stress is obtained.The stress index method for risk evaluation of coalbursts before mining is proposed,and the deformation localization prediction method of coalbursts is put forward.The relationship between energy release and absorption in the process of coalbursts is found,and the prevention and control methods of coalbursts,including the regional method,the local method and support,are presented.The safety evaluation index of coalburst prevention and control is put forward.The integrated prevention and control method for coal and gas outbursts is proposed.The prevention and control technology and equipment of coalbursts have also been developed.Amongst them,the distribution law of the critical stress in China coalburst mines is discovered.The technology and equipment for monitoring,prevention and control of coalbursts,as well as for integrated prevention and control of combined coalbursts and other disasters,have been developed.The energy-absorbing and coalburst-preventing support technology for roadways is invented,and key engineering parameters of coalburst prevention and control are pointed out.In China,coalburst prevention and control laws and standards have been developed.Technical standards for coalbursts are formulated,statute and regulations for coal mines are established,and regulatory documents are promoted.

1.Introduction

Coalburst is a dynamic phenomenon in coal mines which is caused by the instantaneous release of elastic energy accumulated in coal and rock around roadway or working face.When a coalburst occurs,the roadway or working face from several meters to several hundred meters is destroyed instantly.This often leads to roadway blockages,equipment damage,and casualties (Cook et al.,1966;Zhang,1987;Pan,1999;Driad-Lebeau et al.,2005;Jiang et al.,2014;Hebblewhite and Galvin,2017).

Coalburst is a worldwide problem in mining engineering with the characteristics of suddenness,destructiveness and complexity.In 1783,coalburst was first reported in England.Later on,in dozens of countries and regions such as the United States,Australia,Russia,and Poland,coalbursts occurred from time to time.In recent years,with the increases of mining depth and intensity,the frequency and failure intensity of coalbursts have increased.For example,in 2001,a coalburst accident occurred in Merlebach Mine in France,with a local magnitude of 3.6.In 2007,a coalburst accident occurred at Crandall Canyon Mine in the United States,causing 15 casualties.In 2014,a coalburst accident occurred at Austar Mine in Australia,and two miners died.In 2016,a coalburst accident occurred at the Northern Mine of Komi Republic in Russia,killing 36 people.In 2018,a coalburst accident occurred at China’s Longyun Mine,killing 21 people.In 2022,a high-energy landslide and gas leakage accident occurred at the Zofioka Mine in Poland.

The prevention and control of coalburst is a challenging problem in the field of mining engineering and rock mechanics.Scholars from all over the world have carried out extensive research in five aspects: (1) the causes and mechanisms of coalbursts,(2) the risk evaluation of coalbursts,(3) the monitoring and early warning of coalbursts,(4)the prevention and control technology of coalbursts,and (5) development of equipment preventing and controlling coalbursts.In terms of the causes and mechanisms of coalbursts,scholars have developed and put forward"three criteria theory"(Li,1985),"united instability theory" (Zhang,1985),"three factors theory" (Qi et al.,1997),"dilatancy theory" (Pan et al.,2002) and"disturbance response instability theory"(Pan,2018)on the basis of the theories of"strength theory"(Brauner,1975),"stiffness theory"(Cook et al.,1966),"energy theory" (Cook,1965),and "bursting liability theory" (Bieniawski et al.,1969).These theories reveal the basic principles and conditions of coalbursts from different perspectives,promoting the understanding of the mechanism of coalbursts.The risk evaluation of coalbursts is the comprehensive evaluation of the possibility of coalbursts on different scales,such as the mine scale,the coal seam scale,the mining area scale and the working face scale.Evaluation methods mainly involve the multifactor analysis (Li et al.,2007;Paty?ska and Kabiesz,2009;Kabiesz and Makówka,2009;Patyńska,2013;Maleki and Lawson,2017),the comprehensive index method (Dou and He,2007),the stress index method(Wang et al.,2020;Pan et al.,2023),numerical simulations(Li et al.,2008;Sirait et al.,2013;Gu and Ozbay,2015),etc.The evaluation results provide a basis for the coalburst prevention design of coalburst mines.Monitoring and early warning of coalbursts are carried out through the drilling cuttings method(Orzepowski and Butra,2008),the electromagnetic radiation monitoring technology (Wang et al.,2003;Frid and Vozoff,2005),the microseismic monitoring technology (Pan et al.,2007;Jiang et al.,2007;Mutke et al.,2009;Dou et al.,2016;Lou et al.,2019;Holub et al.,2011),the charge induction technology (Pan et al.,2002) and other technologies,in order to assess the susceptibility of coalbursts by data analysis (Janusz et al.,2017;Mondal et al.,2017;Wojtecki et al.,2022).In the research of coalburst prevention and control,according to the geological and mining conditions of coal mines,scholars have studied the effects of mining protective layers (Potvin,2011;Yardimici and Karakus,2020),coal pillars(Rashed and Peng,2015),mining speed (Drzewiecki,2009),pressure relief blasting(Konicek et al.,2011,2013),coalburst-preventing support (Pan et al.,2003;Li et al.,2019;Kang,2021),and other coalburst prevention technologies and methods.

In this paper,from the perspective of science,technology and management of coalburst prevention and control,coalbursts occurring in China are comprehensively and systematically summarized and analyzed,aiming to further advance the technologies for coalburst prevention and control in coal mines.

2.Overview of coalbursts in China

There are 97% of underground coal mines in China characterized by complex geological conditions,various types of disasters and wide distribution of mines.China’s coal mining conditions are the worst among the major coal-producing countries in the world.In China,36% of coal mines are characterized by complicated or extremely complicated geological structures,whilst 23% by simple geological structures.With the increase in mining depth,the frequency and intensity of existing coalburst mines are increasing,and a few mines with no coalburst history gradually experience coalbursts.The characteristics of coalbursts in China are mainly shown in the following aspects.

2.1.The distribution of coalburst mines

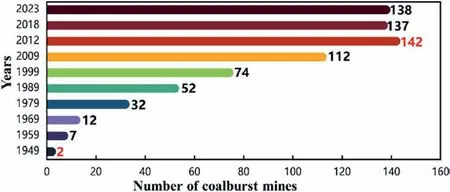

Coalbursts occurred at Shengli Mine in Fushun in 1933,the first time a coalburst accident occurred in China.Subsequently,coalbursts occurred at mines such as Mentougou in Beijing and Tianchi in Sichuan.The number of coalburst mines is increasing year by year (Fig.1).As of September 2023,there are 40 closed coalburst mines and 138 operational coalburst mines in China(Fig.2).These mines are mainly located in 13 provinces,including Shandong,Shaanxi,Inner Mongolia,Gansu,Heilongjiang,Xinjiang and Liaoning.

Fig.1.Changes in the number of coalburst mines.

Fig.2.Distribution of coalburst mines.

2.2.Buried depth of coalburst mines

The average buried depth of coalburst mines in China is 738 m,and those in Shandong and Shanxi Provinces are 952 m and 365 m,respectively(Fig.3).With the increase in mining depth,the length of failed roadways and the number of casualties caused increase(Fig.4).

Fig.3.Buried depth of coalburst mines.

Fig.4.The change of damage with the mining depth.

2.3.Geological and mining conditions

The geological and mining conditions prone to coalbursts include certain lithotypes(lignite and other coal),certain thickness(thin,medium thick,thick and extra thick coal seams),various roofs(such as conglomerate,sandstone and limestone),various coal mining methods (such as long wall and short wall),various coal mining technologies(such as fully mechanized mining and blasting mining),and various mining depths(such as shallow,deep and over 1000 m).There have been coalburst accidents under these conditions(Fig.5).

Fig.5.Coalbursts occurring in various geological and mining conditions.

2.4.Roadway coalbursts

From 1983 to 2023,there were 1355 coalburst accidents in China.The proportion of coalbursts in working face greatly decreased,and the proportion in roadways greatly increased to an average of 93.1%,as shown in Fig.6.

Fig.6.Change of the proportion of roadway coalbursts over time.

2.5.Coalburst under special geo-conditions

As shown in Fig.7,the magnitude of coalburst is high under special geological conditions,such as the presence of a large thrust fault (e.g.at Yima mining area of Henan Province),a thick red soil layer(e.g.in Shandong Province),lacustrine sedimentary roof(e.g.in Ordos mining area)and steeply inclined coal seam(in Wudong,Xinjiang).

Fig.7.Cases of coalbursts under special geological conditions.

2.6.Mine earthquakes

Mine earthquakes are dynamic phenomena with a sense of earthquakes in the mining area.They mostly occur in the goaf of adjacent working faces.In recent years,mine earthquakes have occurred frequently in Inner Mongolia,Shaanxi,Shanxi,Shandong,Liaoning,Jilin and other areas.For example,the "March 24,2020"mine earthquake event at Shilaowusu Mine,having a magnitude of 2.9.The "May 1,2020" mine earthquake event at Hongyang No.3 Mine,having a magnitude of 2.1.The "June 30,2020" mine earthquake event at Madaotou Mine,having a magnitude of 2.0.The"December 15th,2020" mine earthquake event at Jinjitan Mine,having a magnitude of 2.6,and the "June 11th,2021" mine earthquake event at Hongqinghe Mine having a magnitude of 3.0.When the above-mentioned events occurred,tremors were barely felt underground and obviously felt at the ground surface.Most of mine earthquakes are"earthquakes without disasters",thus the concept of not controlling mine earthquakes but controlling coalburst has been formed for a long time.But with the increase in mining depth,mine earthquakes may induce coalbursts.

2.7.Combined disasters

In deep regions,the stress increases significantly,which leads to the coexistence of coalbursts and other disasters (Fig.8).For example,on February 14,2005,a combined disaster of coal and gas outbursts occurred at Sunjiawan Mine,killing 214 people.On August 7,2005,a combined disaster of coalburst and water inrush occurred at Daxing Mine,killing 123 people.On June 5,2008,a combined disaster of coalburst and fire occurred at Yima Qianqiu Mine,killing 13 people.On October 20,2018,a combined disaster of coalburst and roof caving occurred at Longyun Mine,killing 21 people.There are 47 mines with combined disasters of coal and gas outbursts,98 mines with combined disasters of coalbursts and roof caving,62 mines with combined disasters of coalbursts and fire,and 41 mines with combined disasters of coalbursts and water inrush.

Fig.8.Combination of coalbursts and other disasters.

3.Theory of coalbursts

In the late 1970s and early 1980s,coalburst disasters in China began to attract attention.Due to the unclear mechanism of coalbursts,there are many problems to control these disasters in practice.Bounded by the hypothesis of "strength,stiffness and energy",focuses were placed on where coalburst appears,which limits the observation range,and which makes the prediction of coalburst inaccurate.On the other hand,coalburst was regarded as a kind of "natural disaster",and the concept of “monitoring-forecasting-solving” was adopted,which reduced the effectiveness of coalburst prevention and control.

In 1987,Zhang (1987) put forward the instability theory as the mechanism for coalbursts.In the theory,a coalburst is regarded as a kind of instability phenomenon of mechanical system composed of surrounding rocks of a roadway or a working face under external disturbance.This kind of phenomenon is a physical instability problem caused by the softening nature of material constitutive properties.The occurrence of coalbursts is explained in principle.

On the basis of the research on the mechanism of coalbursts,Prof.Yishan Pan constructed the coal-rock deformation system of coalbursts after 40 years of continuous research.The system uses a control variable,a disturbance variable and a response variable to describe coalbursts.The critical stress formula of coalbursts is obtained.The stress index method of risk evaluation and the localization method of risk prediction are presented.The method of regional and local stress and energy regulation is developed.The method of mine safety evaluation and the integrated prevention and control method of combined coalburst and outburst disasters are put forward.The aforementioned components are formulated as a systematic disturbance response instability theory of coalbursts.

3.1.Coal-rock deformation system

The basic units such as coal seams,working faces,roadways and goafs in the underground mining area of a coal mine altogether form an object system (Fig.9).Although coalbursts are characterized by the instantaneous release of elastic energy accumulated in the coal and rock around the roadway or working face,the intensity of coalbursts is not only determined by the local coal and rock deformation of the roadway and working face,but also related to the coal and rock deformation of the whole object system.The object system changes constantly with mining.Taking the area where coalbursts occur (roadways and working faces) and the surrounding environment as a whole,a coalburst deformation system with dynamic evolution characteristics is proposed,which is composed of coal seams,roofs and floors,structures,roadways and working faces.

Fig.9.Object system in coal mine.

Three variables,i.e.a control variable,a disturbance variable and a response variable,are proposed to describe the deformation system of coalbursts(Fig.10).The magnitude of the three variables determines whether the coal-rock deformation system is in the critical state to cause coalbursts.

Fig.10.Control,disturbance and response variables of a coal-rock deformation system.

3.2.Mechanism of coalbursts

Under the influence of mining activities,the stress around the roadway or near the wall of the working face exceeds the peak strength,which consumes energy in the form of plastic softening.During this process,the surrounding elastic rocks store energy.Under continuous mining disturbances,the stable equilibrium state is lost,the elastic zone releases energy,and the plastic softening zone and support absorb energy.The remaining energy is converted into kinetic energy,resulting in coalbursts (Fig.11).

Fig.11.A schematic of the mechanism of coalbursts.

3.3.Critical stress to trigger coalbursts

It is found that the bursting liability of coal is the most important control variable of the coal-rock deformation system.The index of bursting liability includes the time of dynamic failure,elastic energy index,bursting energy index and uniaxial compressive strength,as shown in Fig.12.Through laboratory tests,the bursting liability can be divided into three grades: no bursting tendency,weak bursting tendency and strong bursting tendency.

Fig.12.Bursting liability of coal.

The disturbance response criterion for coalburst occurrence is proposed through the load path extreme point method and the energy maximum method (Fig.13).The critical stress formula to trigger coalbursts is obtained.Although the expressions obtained by the two methods are different,the error is only 1%,thus the formula can be used.

Fig.13.Disturbance response criterion and critical stress for coalburst occurrence.

The feasibility of the theoretical formula is proved by experimental research (Fig.14).Verified by coal and rock material tests,the error between theoretical and experimental values of the critical stress is 1.9%.Verified by similar simulation tests,the error between theoretical and experimental values of the critical stress is 5.7%.

Fig.14.Experimental verification of critical formula of coalburst.

In order to reduce the errors caused by the assumptions of circular cross-sections of roadways,equal pressures and homogeneous properties,a calculation method for the correction coefficient η of the critical stress formula is proposed.Based on coalburst cases in 20 mines,assuming that the approximate actual stresspis equal toPcr,the correction coefficient η of the mines is obtained by back calculation:

where η=1.63+22.09×0.8σc,and σcis the uniaxial compressive strength.

3.4.Stress index method for evaluating the risk of pre-mining coalbursts

The ratio of the actual stressPto the critical stressPcris defined as the stress indexWP.The calculation formula of the actual stress and the supporting stress is put forward:

Amongst them,the actual stress is calculated by the following formula:

wherePzis the stress due to gravity;andKfis the stress concentration factor of surrounding rocks,which can be written as

whereKfiis the stress concentration factor for each influencing factor,andnis the number of influencing factors.

The calculation formula of the roadway support stress is as follows:

whereFsis the sum of the supporting stress of all supporting equipment within the unit distanceL,LCis the perimeter of the roadway,Fmgis the sum of supporting stresses of the anchor within the range of unit distanceL,Fmsis the sum of supporting stresses of the anchor cable within the unit distanceL,FUis the sum of the supporting resistance of U-shaped steel within the unit distanceL,andFzjis the support stress of the support within the range of unit distanceL.The unit distanceLis usually 1 m.

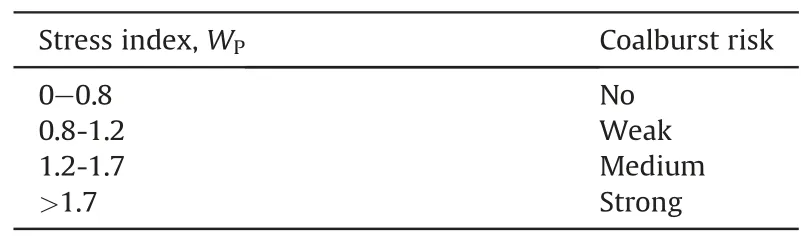

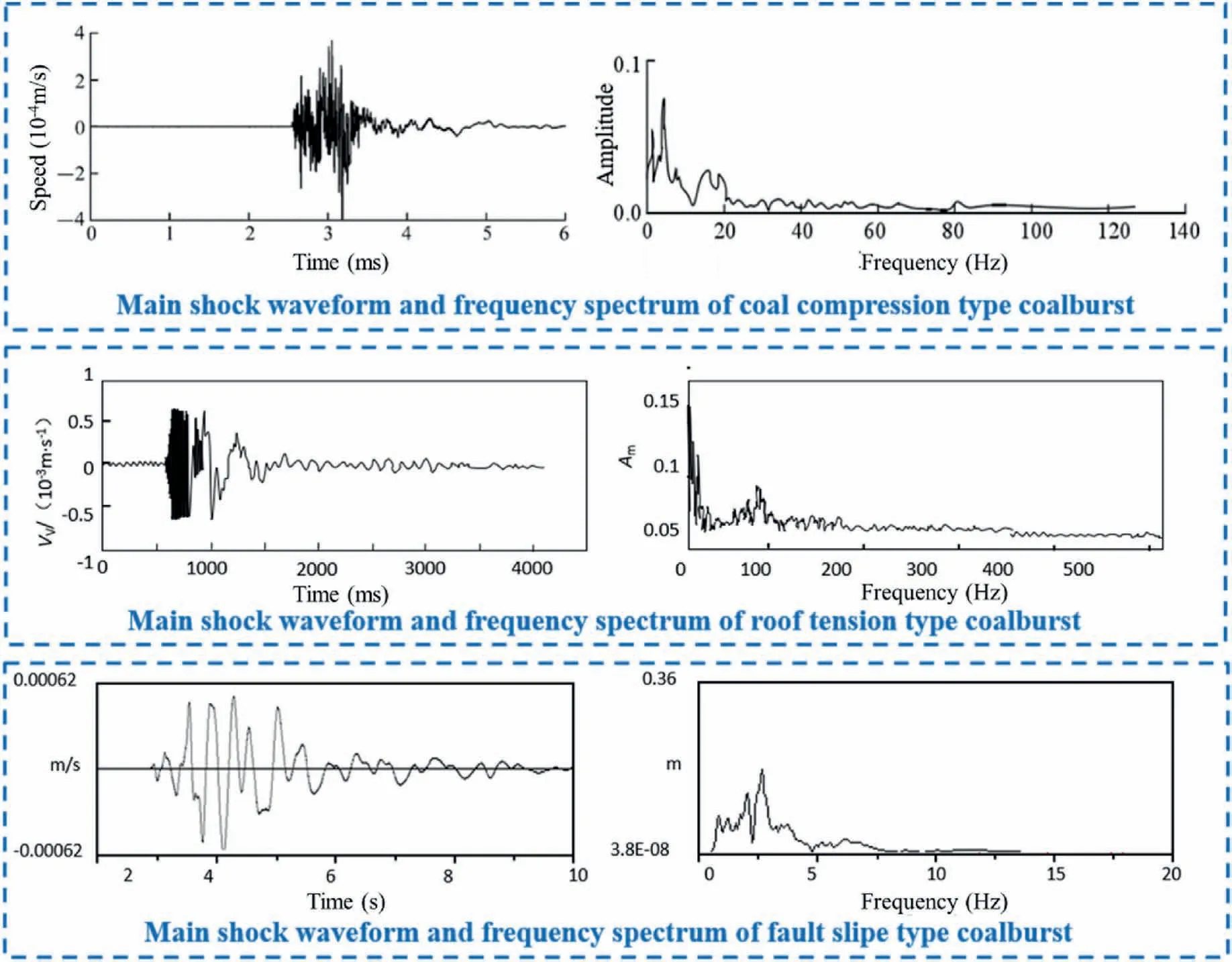

The concept of evaluating the coalburst risk and dangerous areas according toWPis put forward,and the quantitative evaluation of coalburst risk before mining is realized (Table 1).

Table 1Classifications of coalburst risk.

3.5.Prediction method for coalbursts

It is found that the deformation field concentrates in a certain area before coalbursts occur,showing localization of deformation and failure.The localization of deformation and failure intensifies with the vertical loading (Fig.15).

Fig.15.Evolution process of the localization of deformation: (a) Pre-peak stress stage,and (b) Post-peak stress stage.

The key index of deformation localization is put forward,and the location of coalburst occurrence is predicted by monitoring the localization index.

The localization index is presented as follows:

According to the change of signal gradient and curvature,the damaged spatial structure is obtained.

The signal observation value is expressed by

The signal estimation value can be written as

The gradient estimation value is

The curvature change estimation value is

3.6.Relationship of energy release and absorption of the coal-rock system during coalbursts

The energy released by the deformation system isWo,the energy absorbed by the surrounding rock isWc,the energy absorbed by support isWs,and the residual bursting energy isWr.When a coalburst occurs,the residual energy must be greater than zero:

The standard for the design of coalburst mines is put forward.This involves to ensure that the sum of the energy that can be absorbed by the surrounding rock and support is higher than the predicted maximum energy released by coalbursts,i.e.

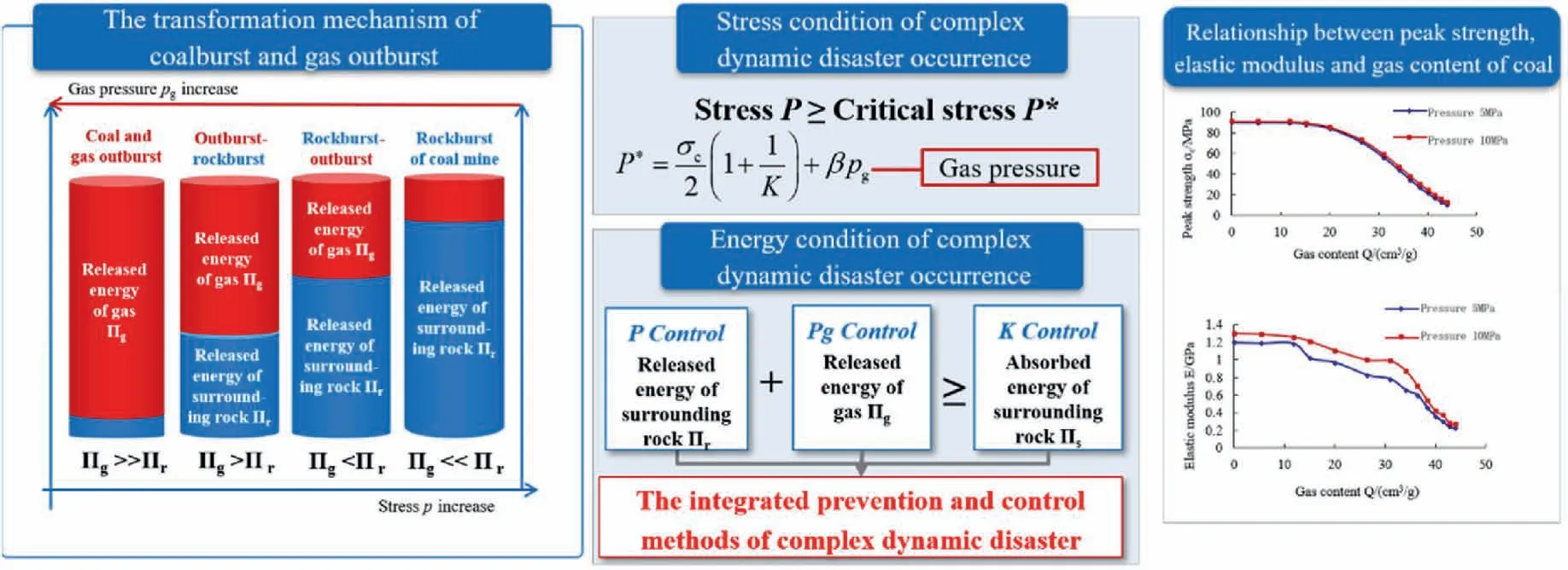

According to the energy release from the coal-rock deformation system,coalbursts are classified into three types,including the coal compression type,the roof tension type and the fault slip type.The energy release formulae of the three types are obtained,as shown in Fig.16.

Fig.16.Maximum energy released from different types of coalbursts.

It is found that fault slip type coalbursts,coal compression type coalbursts and mine earthquakes are all related to friction or ultralow friction.Through experiments,the laws of interlayer friction and energy release due to instability of faults are obtained(Fig.17).

Fig.17.Experimental research on energy released by frictional instability.

The calculation formula of energy absorption in plastic softening zone of surrounding rocks and roadway supports is obtained.The formula of absorbed energy in plastic zone of surrounding rock is expressed by

The formula of energy absorbed by roadway support is expressed by

whereUmgis the energy absorbed by bolts,Umsis the energy absorbed by anchors,Uzjis the energy absorbed by supports,andUuzis the energy absorbed by U-sheds.

A hydraulic impact tester which could release 4000 kJ of energy with the load of 6500 kN at a speed of 8 m/s within 50 ms is invented (Fig.18).It lays a foundation for research on the energy absorption law.

Fig.18.The 6500 kN hydraulic bursting tester.

The energy absorption law of surrounding rocks and supports is found.Through large-energy impact tests,the energy absorption law of coal and rock specimens,energy absorption device and hydraulic column under the condition of coalbursts is discovered(Fig.19).It lays a foundation for the support and energy absorption design to prevent coalbursts from occurring.

3.7.Mechanism for the prevention and control of coalbursts

Control,disturbance,and response variables of coal-rock systems are presented.The coalburst occurrence is controlled by adjusting the stress and energy.The research directions of reducing the environmental stress and increasing the critical stress to trigger coalbursts,and reducing the released energy and increasing the absorbed energy are proposed for the prevention and control of coalburst,as shown in Fig.20.

Fig.20.Principles of stress and energy regulation of coalbursts.

3.8.Safety evaluation index of the coalburst prevention and control

By analyzing the coalburst accidents in China in the past 40 years(Fig.21),it is found that the stress concentration,failure zone,and energy release are limited.Casualties can be avoided if the shrinkage rate of roadway sections is less than 20%.

Fig.21.Statistics of coalburst failure in China:(a)Stress concentration,(b)Energy released,(c)Failure length of roadways,and(d)Casualties and shrinkage rate of roadway crosssection.

The stress safety index and the energy safety index are proposed for the first time.Division of safety standards is presented in Table 2.The stress safety index is defined as the ratio of the critical stress to the actual stress:

Table 2Division of safety standards.

The greater the stress of surrounding rocks of the roadway,the smaller the stress safety index.Therefore,reducing the stress surrounding the roadway or increasing the critical stress value of the roadway can increase the stress safety index of the roadway,which is conducive to preventing coalbursts.

The energy safety index is defined as the ratio of the sum of absorbed energy by support and near-field absorbed energy to the far-field released energy of surrounding rocks,i.e.

When the energy safety indexSen>1,we have

There is no residual energy.If the overall support is in good conditions and the shrinkage rate of the cross-section is less than 20%,no casualties will be caused.

3.9.Integrated prevention and control method for combined coal and gas outbursts

The mechanism of combined dynamic disaster occurrence is revealed,and the stress and energy conditions of disaster occurrence are obtained.The transformation mechanism of coal and gas outbursts is found,and the integrated control method for combined dynamic disaster is put forward to allow the steady-state and orderly energy release in the deformation system of the gas-solid two-phase media,as shown in Fig.22.

Fig.22.Principle of integrated prevention and control method for combined disasters.

4.Practice of coalburst prevention and control

In the early 1980s,technologies for coalburst control from Russia,Germany,Poland and other countries are not suitable for China’s coal mine geology and mining conditions,which makes the coalburst not being effectively controlled.In the mid-1980s,Zhao(1987),Zhang et al.(1988) and other scholars began to investigate coalburst cases in China.Through the continuous efforts of experts,scholars,field engineers and technicians,the coalburst prevention and control system in China has been gradually formed(Fig.23).

Fig.23.Situation of coalbursts and relevant controlling technologies in 1980s: (a) Coalbursts that occurred at Mentougou Mine in Beijing,and (b) Monitoring and forecasting technologies for coalburst control.

4.1.Distribution law of critical stresses in China’s coalburst mines

It is found that there is a critical mining depth of coalbursts in every mine.When it is less than this depth,coalbursts hardly occur(Fig.24).When it is greater than this depth,coalbursts frequently occur.

Fig.24.Critical mining depth of coalbursts:(a)Relationship between number of coalbursts and mining depth at Huafeng Mine,and(b)Relationship between number of coalbursts and mining depth at Mentougou Mine.

According to the relationship between the mining depth and in situ stress,the critical depth essentially represents the critical stress(Eq.(18)).The critical stress of coalburst mines is the basis of quantitative evaluation of coalburst risk before mining.

wherePcris the critical stress,Hcris the critical depth,and γ is the volumetric weight of overlying strata.

The coal bursting liability of coalburst mines in 13 provinces in China was counted,as shown in Fig.25.The average uniaxial compressive strength of coal seams from these mines was 13.21 MPa,and the average bursting energy index was 3.89.

Fig.25.Statistics of average bursting energy index and uniaxial compressive strength of coal seams from coalburst mines in 13 coal-producing provinces of China.

The critical stress of 127 coalburst mines in China was obtained,as shown in Fig.26.It is found that the greater the bursting energy index,the smaller the critical stress.The average value of the critical stress is 30.72 MPa.

Fig.26.Critical stresses of 127 coalburst mines in China.

4.2.Ground intelligent microseismic monitoring technology and equipment

The early warning system for coalburst control is constructed(Fig.27).It is proposed that the location and time of coalbursts can be predicted by monitoring methods such as microseismic monitoring,stress monitoring and drilling cuttings observation.A method combining the regional method and the local method is put forward:the regional monitoring covers the whole mine range,and the local monitoring covers the dangerous zone of coalbursts.Decision is made according to the comparison between the monitored value and the critical value.If the monitored value is lower than the critical value,no danger is forecasted.If it is greater than the critical value,the risk level is forecasted and corresponding measures are taken.

Fig.27.Monitoring and early warning system for coalburst control in China.

For the deformation system,methods such as microseismic monitoring and surface subsidence monitoring are adopted to monitor the stress and energy changes in the whole mining area.

The conventional microseismic monitoring system has many problems,e.g.the stations are arranged at the boundary of underground,the stations need to move frequently with the advance of working face,the effective monitoring range is small,the sampling frequency is low,the time synchronization accuracy is poor,the timing error is large,and the wired networking mode is limited.In this end,the ground intelligent microseismic monitoring technology and equipment are developed (Fig.28).

Fig.28.Monitoring and early warning system for coalburst control in China.

The system effectively integrates the P-wave arrival picking method under different applicable conditions,the intelligent adaptive positioning algorithm under different noise conditions,the intelligent classification method combining neural network and migration learning,and the spatio-temporal strong prediction method based on deep learning and deformation localization,the time series database and Internet of things (Iot) data platform(Fig.29).

Fig.29.Index of the ground intelligent microseismic monitoring system.

The microseismic evaluation method of coalburst types is put forward.As shown in Fig.30,the main shock amplitude of coal compression type coalbursts is large,and the high-amplitude vibration lasts for a long time,but it decays quickly.The low frequency component (0-20 Hz) of the main shock accounts for a large proportion.Most of the magnitude is 0-1.5.The duration of coal compression coalbursts is within 0.5 s,and the dominant frequency is about 25-35 Hz.The waveform characteristics of roof tension type coalbursts are S waveform and low frequency.The development period of surface wave is long,and the vibration frequency of P wave with S wave and C interference is low,and the magnitude is mostly 1.5-2.5.The duration of roof tension coalbursts is 0.5-5 s,and the dominant frequency is about 15-25 Hz.The waveform characteristics of fault slip type coalbursts are closer to those of earthquakes,with low frequency and large energy carried by stress waves.The main earthquake frequency is mainly distributed in 0-5 Hz,and the magnitude is mostly 2.5-3.5.The duration of fault slip coalbursts is about 5-30 s,and the dominant frequency is 1-6 Hz.

Fig.30.Typical waveforms and spectrograms of different coalburst types.

A deformation localization method for coalburst prediction is proposed(Fig.31).Based on the theory of deformation localization,the spatial location,magnitude and energy release of coal and rock fracture are assessed to realize the early warning of coalbursts.The fracture initiation/propagation occurs in the stress concentration area in front of the working face,the area near the goaf,and the area near the roadway,which shows that the stress concentration area near the working face has a high risk of coalbursts.

Fig.31.Localization method of deformation and failure for coalburst prediction.

The response variable is monitored,including the drilling cuttings method,the borehole stress gauge method,the support load method,the roadway deformation measurement method,the ground sound monitoring method,the electromagnetic radiation monitoring method,and the charge monitoring method.

By detecting and analyzing the charge generated by coal-rock deformation and fracture,the mechanical process of coal-rock deformation and fracture can be controlled,and then the prediction of coalbursts can be realized (Fig.32).

Fig.32.Monitoring of coalburst charges.

The method for determining the warning index for coalbursts is put forward.According to laboratory tests and referring to adjacent mines,the initial value of the warning index is determined,subjected to continuous correction in practice (Fig.33).The microseismic method uses microseismic energy as the main warning index,the drilling cuttings method uses the drilling cuttings quantity as the main warning index,and the stress method uses the stress value as the warning index.When an index reaches or exceeds the early warning critical value,a warning for coalburst occurrence will be triggered.

Fig.33.Determination of the early warning index for coalbursts.

4.3.Technologies and equipment for regional and local prevention and control of coalbursts

The technical system of coalburst prevention and control is constructed (Fig.34).The prevention and control principles of coalbursts are put forward,including first applying regional methods,then implementing local methods,followed by zonal management,and prevention and control by classification.

Fig.34.The coalburst prevention and control system in China.

Technical innovation of regional prevention and control of coalbursts is promoted (Fig.35).The regional prevention and control technology of coalbursts is put forward,including mining area division,reserving mining protective layer,optimal design of roadway layout,applying working face pushing mining,optimizing coal pillar setting,and applying filling mining.

Fig.35.Regional technologies for coalburst prevention and control.

As shown in Fig.36,different prevention methods are adopted for coal compression type coalbursts,roof tension type coalbursts and fault slip coalbursts.

Fig.36.Prevention and control techniques for different coalburst types in China.

At present,the local technologies for coalburst prevention and control in China mainly include large-diameter drilling,coal seam water injection,coal seam blasting and roof blasting (Fig.37).Large-diameter drilling uses the elastic energy accumulated in the coal seam under the condition of high stress to destroy the coal body around the drilling hole,so as to weaken the mechanical properties of the coal seam,reducing the stress of the coal seam and thus the risk of coalbursts.Coal water injection changes physical and mechanical properties of coal and the bursting liability.With the increase of water contents,the mechanical parameters of coal are significantly reduced,and the ability to absorb energy is enhanced.Coal blasting reduces the uniaxial compressive strength of coal,reduces the elastic energy stored in coal,and enhances the ability of the coal seam to absorb energy.Roof blasting can reduce the static load of coal formed by hanging roof,effectively reducing the energy accumulated in roof strata.On the other hand,it is more conducive to reducing the dynamic impact load caused by largescale roof fracture or collapse,reducing the dynamic energy release,thus reducing the risk of coalbursts.

Fig.37.Local technologies for coalburst prevention and control.

4.4.Energy absorption and support technology to prevent roadway coalbursts

In deep mining,the ground stress is high and the disturbance is strong.Especially in Xinwen (Shandong),Yima (Henan) and other mining areas,there is a risk of huge thick roof stretching and large fault slip,with energy release up to 108J.This induces coalbursts,resulting in serious damage to roadway support and casualties.It is difficult to control the large energy released in the far-field triggered by high stress and strong disturbance.The interaction process between roadway support and surrounding rocks during coalbursts is not well understood.Traditional support is difficult to adapt to the strong dynamic load,high speed and large energy power action.It is a worldwide challenge to overcome these technical problems.

A series of energy absorption devices is invented as shown in Fig.38.By constructing plastic hinge lines and hinge points,the overall buckling yield and high-speed energy absorption are induced to ensure the resistance,yield and energy absorption functions of the supporting equipment.

Fig.38.Research and development of energy absorption devices: (a) Thin-walled crease-induced energy absorption devices,(b) Thin-walled ripple-induced energy absorption devices,and (c) Testing of absorption devices.

Fig.39.Energy-absorbing anchor cables.

Fig.40.Circumferential shrinkable energy-absorbing O-shaped sheds.

Energy-absorbing support equipment to prevent coalbursts is invented (Figs.39 and 40).Under impact loads,the energy absorption tray at the end and the energy absorption sleeve at the middle of the energy-absorbing anchor cables can absorb energy adaptively.Compared with ordinary anchor cables,the energy absorption capacity of the energy-absorbing anchor cables is increased by 2 times.Under impact loads,the bracket of energyabsorbing O-shaped sheds shrinks and maintains the overall structure to support surrounding rocks,with adaptive sliding energy absorption at the lap joint.The energy absorption capacity of a single bracket is 120-200 kJ.

Energy-absorbing hydraulic support is invented (Fig.41).Thinwall folded and corrugated induced energy-absorbing devices are invented to realize"resistance","yielding"and"energy absorption".These series of roadway support equipment such as door-type support,unit-type support,and step-type support are developed.

Fig.41.Energy-absorbing hydraulic support to prevent coalbursts.

Research on the three-stage energy-absorbing support technology is based on the energy.Through the radial deformation of energy-absorbing anchor cables,circumferential expansion of energy-absorbing O-shape sheds,and axial stabilization control of energy-absorbing hydraulic support,absorption of different levels of released energy from coalbursts is realized.The support can resist the large energy impact of 108 J.According to the magnitude of energy released from coalbursts,coalbursts are divided into three energy levels: 10-100 kJ,100-1000 kJ,and more than 1000 kJ,which respectively require implementing the"anchor-netrope","anchor-net-rope"+U-shape shed,and "anchor-netrope"+U-shape shed+hydraulic support" to prevent coalbursts from occurring.

4.5.Integrated technology and equipment for prevention and control of combined disasters

The combined disasters of coal and gas outbursts involve both coal and rock pressures and gas pressure,thus integrated monitoring is required.A single-hole multi-parameter composite dynamic disaster integrated monitoring device was invented,which can realize synchronous monitoring of drill pipe thrust,torque,drilling cuttings and other parameters,as shown in Fig.42.

Fig.42.A single-hole multi-parameter composite dynamic disaster integrated monitoring device.

The integrated technology for prevention and control of combined disasters has been developed (Fig.43).This overcomes the problem of steady-state regulation of elastic strain energy and gas energy from surrounding rocks.

Fig.43.Integrated prevention and control of combined coal and gas outburst disasters.

4.6.Key parameters of coalburst prevention and control

Through field practice,key parameters such as bursting liability,mutual disturbance distance between mining and excavation,the distance of advance with support,and localized prediction index of coalbursts are put forward,which are widely used in China’s coalburst mines,as tabulated in Table 3.

Table 3Key parameters for coalburst prevention and control.

4.7.Typical cases of effective coalburst prevention and control

The mining depth of Hongyang No.3 Mine in Liaoning Province is more than 1000 m(Fig.44).This mine is a coalburst mine and a coal and gas outburst mine.On November 11,2017,a coalburst caused 10 deaths.After the accident,post-disaster treatment was carried out through evaluation and prediction of post-disaster resumption of production,reserving mining protective layers,pressure relief through coal seam drilling,and implementing prevention and control technology using coal seam water injection.After the treatment,the microseismic energy is released smoothly and the periodic weighting is not obvious,which has achieved remarkable prevention and control.Since the resumption of mining in January 2018,the mining of 9 working faces has been completed successively and safely.

Fig.44.Prevention and control of a coalburst at Hongyang No.3 Mine.

The mining depth of Longyun Mine in Shandong Province is more than 1000 m,and a major coalburst accident occurred in 2018,killing 21 people (Fig.45).The post-disaster treatment was carried out by using the research results of coalburst evaluation,monitoring and design.The number of small energy events below 105J increased greatly,and there were only three large-energy microseismic events above 105J occurring.Since the resumption of mining in 2019,safe mining has been realized.

Fig.45.Prevention and control of coalburst at Longyun Mine.

Longjiapu Mine in Jilin Province has a mining depth of more than 1000 m,with hard roof and large faults (Fig.46).On June 5,2019,a coalburst accident occurred,killing 9 people and stopping production for more than one year.Energy-absorbing support technology was adopted to control post-disaster coalbursts,and safe mining has been realized since the resumption of mining in 2020.

Fig.46.Prevention and control of coalbursts at Longjiapu Mine.

5.Management of coalbursts in China

The prevention and control of coalbursts is a systematic project,and each process involved in coal mining must be managed scientifically.Through long-term in-depth treatment of coalburst mines (Fig.47),especially dealing with coalburst casualties many times,we found that there are cognitive biases,management loopholes,and lags in laws and regulations for the management of coalbursts,hence it is imperative to implement and standardize the management of coalburst prevention and control.

Fig.47.Field investigation of coalburst accidents.

5.1.Technical standards for coalburst control in China

Since 2010,China has gradually formed the coalburst management standards in terms of measurement,monitoring,prevention and control,which consist of 14 parts.Recommended national standards,such as pressure relief prevention methods through coal seam drilling,monitoring methods for cuttings,and coal seam water injection,were put forward and formulated (Fig.48).These national standards were successively promulgated and implemented in 2019-2020.According to statistics,pressure relief prevention methods through coal seam drilling were applied in all the coalburst mines in China.

Fig.48.Application of local technologies for coalburst prevention and control in China.

5.2.Statutes and regulations for coal mines in China

In previous years,national standards were not mandatory,and the on-site implementation was not strong.Therefore,the detailed rules for preventing and controlling coalbursts in China were compiled.In 2017,we compiled the Detailed Rules for the Prevention and Control of Coalbursts,and put forward the principle“first taking regional methods,then implementing local methods,followed by zonal management,and preventing and controlling by classification".The Detailed Rules were released in 2018 and enforced nationwide.Some provisions were outdated in 2023,which made it difficult to comply with the requirements of coalburst prevention and control in the new stage.In this June,we completed investigations of all 138 coalburst mines in China,based on which we carried out the revision of the Detailed Rules for the Prevention and Control of Coalbursts.The revised version will be released and implemented in 2024.

The identification of coalburst mines is the first step to carry out the prevention and control,and the identification result directly affects the characteristics of coalburst mines.In 2021,we carried out the compilation of the Interim Measures for the Identification of Coalburst Mines,which was released in 2023 and enforced nationwide.The supervision department for coalbursts has identified some problems,such as vague law enforcement boundary,law enforcement basis and law enforcement embarrassment.In 2019,we compiled the national "Guidance Manual for Supervision of Coalburst Prevention and Control",refined 46 inspection items,and made clear what to check and how to check.This guidance manual was released and implemented in 2020.

"Coal Mine Safety Regulations" is the most important part of China’s coal mine safety production legal system.In 2023,entrusted by the National Mine Safety Administration of China,the revision of the coalburst part of the Coal Mine Safety Regulations will be carried out,and this will be released and implemented in 2024.

5.3.Promulgation of national and local regulatory documents

Under the impetus of industry experts,the National Mine Safety Administration issued the Notice on Strengthening the Prevention and Control of Coalbursts,the Basic Requirements and Grading Methods of the Standardized Management System of Coal Mine Safety Production,and other notification documents.Shandong Province issued the Measures for the Prevention and Control of Coalbursts in Shandong Province in the form of government orders,and Liaoning,Shaanxi,Hebei,Henan and other provinces also issued regulatory documents on coalbursts.

5.4.Promotion of coalburst prevention and control and the internationalization of research results in China

China’s academic conferences on prevention and control of coalbursts were held,consisting of 4 consecutive sessions and attracting a cumulative attendance of over 100,000 people.During the epidemic period,free online consultation activities were provided for 22 coalburst mines of 13 coal mining enterprises.The first textbook“Coalburst Engineering"was published,which was used as a course textbook by 19 universities in China.The journalGeohazard Mechanicswas founded,and it was selected as the new highstarting point journal of China Sci-tech Journal Excellence Action Plan,which promoted the internationalization of the research results of coalburst prevention and control.

5.5.A system of regulations and standards for coalburst prevention and control

A system of regulations and standards for the prevention and control of coalbursts has been formed,which combines national departmental regulations,regulatory documents,national standards and local documents on coalbursts with characteristics of China’s outburst cases(Fig.49).The system has been implemented in China’s coal mining enterprises,supervision departments,relevant scientific research institutes and universities.

Fig.49.A system of regulations and standards for the prevention and control of coalbursts in China.

Fig.50.Statistics of coalburst accidents in China.

Fig.51.Prevention and control of coalbursts in China during 2019-2023.

5.6.Effective control of casualties from coalbursts

The number of coalburst accidents,the number of casualties,and the death rate per one million tons of coal production have been greatly reduced through the mandatory implementation of the regulations and standards system (Figs.50 and 51).In particular,there was 0 coalburst accident in China in 2022.

6.Conclusions and prospects

Over the past 40 years,with the joint efforts of scholars and field engineers and technicians,remarkable achievements have been made on coalbursts in terms of theoretical development,risk evaluation,monitoring and early warning,prevention and control,legal documents and management system.In this paper,the theory,practice and management of coalbursts in China are analyzed from the “stress and energy” and “regional and local” perspectives.Conclusions can be drawn as follows:

(1) From the perspective of stress and energy,the theoretical system of coalbursts is constructed.The research results mainly include revealing the mechanism and conditions of coalburst occurrence,obtaining the critical stress,proposing the stress index method for evaluating the coalburst risk before mining,proposing the localization prediction method,proposing the analysis method of energy release and absorption,proposing the method of regional and local stress and energy regulation,proposing the stress and energy index of coalburst safety evaluation,and proposing the integrated prevention and control method for combined coal and gas outburst disasters.

(2) From the regional and local perspectives,the practice of coalburst prevention and control is carried out through the regulation of stress and energy.The research results mainly include building a technical system for prediction and prevention,developing a ground microseismic system for regional monitoring,inventing a charge monitor for local monitoring,promoting regional and local prevention and control technological innovation,and inventing an energyabsorbing and anti-scour support technology for roadways to achieve effective prevention and control of coalbursts.

(3) The technical achievements of coalburst related research are written into statutes and regulations.A system of statutes and regulations on coalbursts with characteristics of China’s outburst cases is constructed,which is implemented in all coalburst mines,guiding and standardizing the prevention and management of coalbursts.

(4) The research on coalbursts has shifted from emphasizing on qualitative mechanism analysis to the systematic in-depth research on prevention and control practice.Further indepth and detailed research work is needed to strengthen the research on the basic theory of disaster rock mechanics,which includes reasonably determining the safety factor of the design for coalburst prevention,developing the intelligence of coalburst prediction and prevention,implementing the integrated prevention and control of mine earthquakes and coalbursts,improving mining technologies for protective layers,promoting the hydraulic support of the whole roadway,and scientifically identifying coalburst mines.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China-Liaoning Joint Fund Key Project (Grant No.U1908222) and the National Natural Science Foundation of China(Grant No.51774015).

Journal of Rock Mechanics and Geotechnical Engineering2024年1期

Journal of Rock Mechanics and Geotechnical Engineering2024年1期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Insights into carbon dioxide sequestration into coal seams through coupled gas flow-adsorption-deformation modelling

- Tensile strength and failure behavior of rock-mortar interfaces:Direct and indirect measurements

- Failure transition of shear-to-dilation band of rock salt under triaxial stresses

- A performance-based hybrid deep learning model for predicting TBM advance rate using Attention-ResNet-LSTM

- Numerical investigation of geostress influence on the grouting reinforcement effectiveness of tunnel surrounding rock mass in fault fracture zones

- Assessment of compressive strength of jet grouting by machine learning