Effect of Size Change on Mechanical Properties ofMonolayer Arsenene

GUO Juan , LIU Guili, SUN Zhenyu

(School of Architecture and Civil Engineering, Shenyang University of Technology, Shenyang 110870, China)

Abstract: The Young's modulus, shear modulus and Poisson's ratio of monolayer arsenene with different sizes were calculated by finite element method, so as to explore the influence of dimension and orientation on the mechanical properties of monolayer arsenene.The calculation results show that the small size has a significant effect on the mechanical properties of the monolayer arsenene.The smaller the size, the larger the Young's modulus and Poisson's ratio of the monolayer arsenene.The size change has a great influence on the Young's modulus of the arsenene handrail direction, and the Young's modulus of the zigzag direction is not sensitive to the size change.Similarly, the size change has a significant effect on the shear modulus of arsenene in the handrail direction, while the shear modulus in the zigzag direction has no significant effect on its size change.For the Poisson's ratio, the situation is just the opposite, and the effect of the size change on the Poisson's ratio of the arsenene zigzag direction is greater than that of the handrail direction.

Key words: finite element method; arsenene; size change; mechanical properties

1 Introduction

Among two-dimensional materials, graphene,silicene, phosphorene, and antimonene have attracted extensive attention due to their unique structures and physical properties[1,2].Arsenene is a new type of two-dimensional material composed of arsenic atoms[3], with a honeycomb-like structure, and its layered nanosheets have been successfully prepared[4].The research results of many scholars have shown that arsenene has good properties in electrical[5-9], optics[10,11],thermodynamics[12]and mechanics[13,14].Monolayer arsenene is an indirect bandgap semiconductor with a wide bandgap.It has been found that the indirect bandgap to direct bandgap transition can be achieved by applying 4% or 11.7% biaxial tensile strain, respectively, into a direct bandgap semiconductor[15]or a unique two-dimensional topological insulator[16], which means that arsenene can still maintain a direct bandgap semiconductor state in the case of structural deformation,which provides a theoretical basis for the preparation of new semiconductor materials arsenene[17].

At present, the research on arsenene mainly focuses on its electrical properties and optical properties[18-20].At the same time, many scholars have paid attention to the mechanical properties of arsenene, which is based on density functional theory (DFT) , molecular dynamics simulation (MD), and studied the mechanical properties of arsenene[21-23].Yousefiet al[24]used density functional theory to study the structure and mechanical properties of arsenene nanosheets doped with transition metals.The study found that doping with transition metal atoms would lead to a decrease in the Young's modulus of the original structure, and then by comparing the Young's modulus of the original structure and the doped structure in the armchair and zigzag directions, isotropic behavior of arsenene nanosheets were proved.Jianget al[23]established the Stillinger-Weber potential parameters of various curved two-dimensional hexagonal materials, and studied the mechanical properties of two-dimensional materials such as arsenene,silicene, and antimonene through molecular dynamics simulation.The results show that the stress of these two-dimensional materials is proportional to the strain.In a small range, the elastic properties of arsenene and other materials are isotropic, the critical strain range is relatively small, and the chiral effect is displayed from the critical strain direction.Aghdasiet al[25]used density functional theory to study the effect of adsorption on the elastic and plastic properties of arsenic.The results show that the transverse Young's modulus decreases in all adsorbed structures, while in the longitudinal Young's modulus, the amount of adsorption leads to an increase in the Young's modulus.A study of the longitudinal and transverse Young's modulus of pristine and adsorbed arsenic showed the anisotropic behavior of these structures.Luoet al[26]used the first-principles method to study the effect of different chirality and size on the structure of arsenene nanobelts.The results show that the band gap of each of the considered arsenic nanoribbons can be reduced with increasing size.Guoet al[32]theoretically calculated the bulk modulus, shear modulus, Young's modulus, Poisson's ratio and other mechanical parameters of monolayer arsenene, and predicted the shear anisotropy of the arsenene structure.

The outstanding feature of nanotechnology is that the properties of nanomaterials are related to dimension.Due to the extremely small size of nanomaterials,it is very difficult to perform effective experiments at the nanoscale.The research progress of arsenene is still in the stage of theoretical calculation, and it is extremely difficult to use molecular simulation to complete the modeling.The finite element method based on continuum mechanics can be easily modeled.Therefore,based on the finite element method, the related research on two-dimensional materials using this method has been very mature[27-30].To date, numerous studies have focused on the thermodynamic, electrical, and optical properties of arsenene, but its mechanical properties have not been fully explored.The purpose of this paper is to construct 7 computational models of single-layer arsenene structures with different sizes, and to analyze the effects of dimension and orientation on their mechanical properties.

2 Calculation methods and models establishment

2.1 Finite element calculation models of monolayer arsenene

The force behavior of the arsenene structure was simulated and calculated by the equivalent rod system,and the arsenic-arsenic covalent bond of arsenene was regarded as the rod, and the arsenic atom was regarded as the connection point between the rods.The arsenic-arsenic bond has the same form as the deformation energy of the beam element in the case of small deformation, so the circular section beam element is used to simulate the arsenic-arsenic bond.The relevant parameters of the beam element, including diameterd, elastic modulusEand shear modulusG, can be determined by the following formula[32]:

In the formula:YSis the surface Young's modulus,Vis the Poisson's ratio,Dis the flexural rigidity,r1is the length of atomic bonds,kris the tensile constant of covalent bonds,kθis the bending constant of covalent bonds, andkτis the torsion constant of covalent bonds,Lis the length of atomic covalent bonds,dis the radius of beam element,Eis the elastic modulus of beam element, andGis the shear modulus of the beam element.

At first, calculateYS,VandD, which is based on the DFT approach, and then substitute them into Eqs.(1), (2) and (3) to obtain the values of the covalent bonds force constantskr,kθandkτ, respectively.Finally,according to the calculated force constants, the parameters of beam elements such asd,EandGcan be obtained by substituting them into Eqs.(4), (5) and (6).

P Aghdasiet al[31]obtained parameterskr=113.17 nN/nm,kθ=0.64 nN?nm, andkτ=7.79 nN?nm.Based on the DFT method, the optimized covalent bond length of the arsenic atom isL=0.254 7 nm, and the relevant parameters of the beam element of the finite element model are obtained asd=0.150 5 nm,E=4.05×1011N/m2andG=2.468×1012N/m2.This is very close to the calculated radius of 0.151 nm, Young's modulus of 3.99×1011N/m2, and shear modulus of 2.39×1012N/m2calculated in Ref.[31], with errors of 0.33%, 1.63% and 3.16%, respectively, indicating that the parameter settings in this paper are reasonable.

Using the above parameters and formulas, the Young's modulus of the monolayer arsenene model is 54.89 GPa, which is similar to the Young's modulus of 54.74, 53.58 and 50.47 GPa calculated in Refs.[24], [31] and [33], and the errors are 0.27%, 2.39%and 1.04% respectively.The Poisson's ratio is 0.254 5,whichisnot muchdifferent fromthePoisson's ratio(0.2714)obtained byGuoet al[32]through simulation experiments.According to the above comparison, it is verified that the method used in this paper is effective and can predict the results well.

2.2 Establishment of the monolayer arsenene models

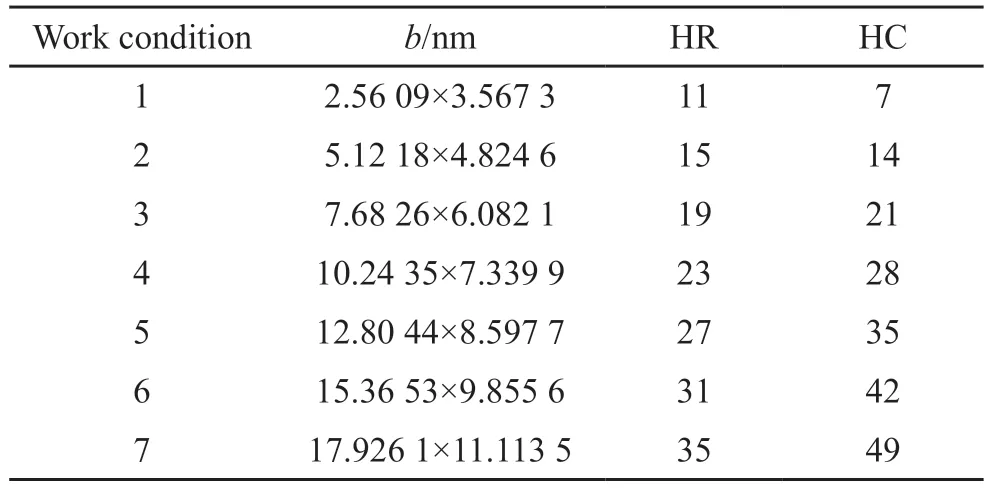

Because the arsenene structure has different stress forms in the handrail direction and the zigzag direction,it is necessary to study the mechanical properties of the monolayer arsenene in the handrail direction and the zigzag direction.But the sizes in the two directions are unequal, and not necessarily exactly equal to an integer.Therefore, select the models that fully displays the hexagon and is the closest to that dimension to study.The ANSYS finite element calculation software is used to simulate it, and the basic element of the beam is used(the BEAM188 element).When building the models,it is assumed that the monolayer arsenene structure has no agglomeration and no wrinkles.Seven computational models of different size were established to study the mechanical properties of monolayer arsenene.The length and width of the monolayer arsenene structure are characterized byaandb, respectively.Table 1 lists the specific size parameters of the 7 working condition models.Because the models are only different in size,the model schematic diagram of the minimum size and the maximum size of monolayer arsenene is selected,as shown in Fig.1.

Fig.1 Schematic diagrams of monolayer arsenene working conditions

Table 1 Model size parameters of 7 working conditions

2.3 Analysis of structural mechanical properties

According to the different edge structures, there are two types of arsenene structures: handrail direction and zigzag direction.Orientation definition of monolayer arsenene structure:The fixed coordinate axis, the direction perpendicular to thex-axis is the handrail direction, and the direction perpendicular to they-axis is the zigzag direction.

The boundary conditions of arsenene in the handrail-shaped direction and the zigzag-shaped direction are different, so the boundary conditions and displacement conditions imposed are also different during the finite element simulation.As shown in Fig.2, one boundary of the monolayer arsenene is fully constrained, and an appropriate small deformation is applied to the other boundary.The amount of tensile deformation in thex-direction in Fig.2(a) and they-direction in Fig.2(b) is set to 1 nm.

Fig.2 Schematic diagrams of the setting of boundary conditions for the monolayer arsenene structure

The Young's modulus, shear modulus and Poisson's ratio of monolayer arsenene were obtained by finite element calculation of the relationship between load and deformation.The monolayer arsenene structure shares some characteristics with graphene, so the elastic constants can only be calculated after assuming its thickness.Arsenene adopts a curved structure to improve its stability, so the interlayer distance of arsenene, that is, the thickness of monolayer arsenene is 0.14 nm[15].

The tensile simulation of arsenene along the handrail-shaped direction is shown in Fig.2(a).After the simulation calculation is completed, the resultant force of the support reaction force of arsenene in thexdirection and the deformation amount of arsenene in thexdirectionΔLxare obtained.Young's modulusEand shear modulusGLxare obtained from Hooke's law, and Poisson's ratiovis obtained from the ratio of transverse line strain to longitudinal line strain.

The tensile simulation of arsenene along the zigzag direction is shown in Fig.2(b).After the simulation is completed, the resultant force of the support reaction force of arsenene in theydirection and the deformation amount of arsenene in theydirectionΔLyare obtained.Young's modulusEand shear modulusGare obtained from Hooke's law, and Poisson's ratiovis obtained from the ratio of transverse line strain to longitudinal line strain.

whereLxis the original length of arsenene in thexdirection,Lyis the original length of arsenene in theydirection, andtis the thickness of arsenene.

3 Results and discussion

3.1 Young's modulus

It can be seen from Fig.3 that the Young's modulus of monolayer arsenene in the handrail direction and the zigzag direction decreases gradually with the increase of the size, and is monotonic; In the 7 working conditions, the Young's modulus of the first working condition (i e, the small size) reaches the maximum value, and the Young's modulus of the seventh working condition (i e, the large size) reaches the minimum value; Whether it is the handrail direction or the zigzag direction, when the size is large enough , the Young's modulus of monolayer arsenene tends to be stable in both directions.

Fig.3 Young’s modulus of monolayer arsenene with different size

It can be seen from Fig.4 that in the calculation model of the same dimension, the Young's modulus values of monolayer arsenene in the handrail direction and the zigzag direction are significantly different,and the former is always larger than the latter; As the size increases , the Young's modulus change curves of monolayer arsenene in the handrail direction shows a monotonically decreasing trend, while that in the zigzag direction is relatively stable, but the overall trend is still monotonically decreasing.The changing proportion curves of Young's modulus in the handrail direction and the zigzag direction all show a monotonically decreasing trend, but the changing proportion curve in the zigzag direction is relatively gentle.

Fig.4 Change and change ratio curves of Young’s modulus of monolayer arsenene

From the above results, it can be seen that the Young's modulus of monolayer arsenene is related to the size, which is consistent with the conclusion of Aghdasi Pet al[31]that the size can affect the Young's modulus of arsenene.The result of this research is that the Young's modulus of monolayer arsenene can be predicted, and the Young's modulus is related to the size.Our study also found that the Young's modulus of arsenene is related to the direction.In the calculation model of the same dimension, the Young's modulus value of the arsenene handrail direction is significantly higher than that of the zigzag direction, indicating that the size change has a significant effect on the direction of the monolayer arsenene handrail direction Young's modulus.The Young's modulus change curve in the zigzag direction of the monolayer arsenene is basically a straight line, and it can be seen that the effect on the zigzag direction is not obvious.From the proportional curves of Young's modulus change, it shows that the influence of size change on the Young's modulus of small-size arsenene is more significant than that of large-size arsenene, and the proportional curves of Young's modulus of large-size arsenene tends to be gentle.It can be seen that the effect on large-size arsenene is greatly weakened.

3.2 Poisson's ratio

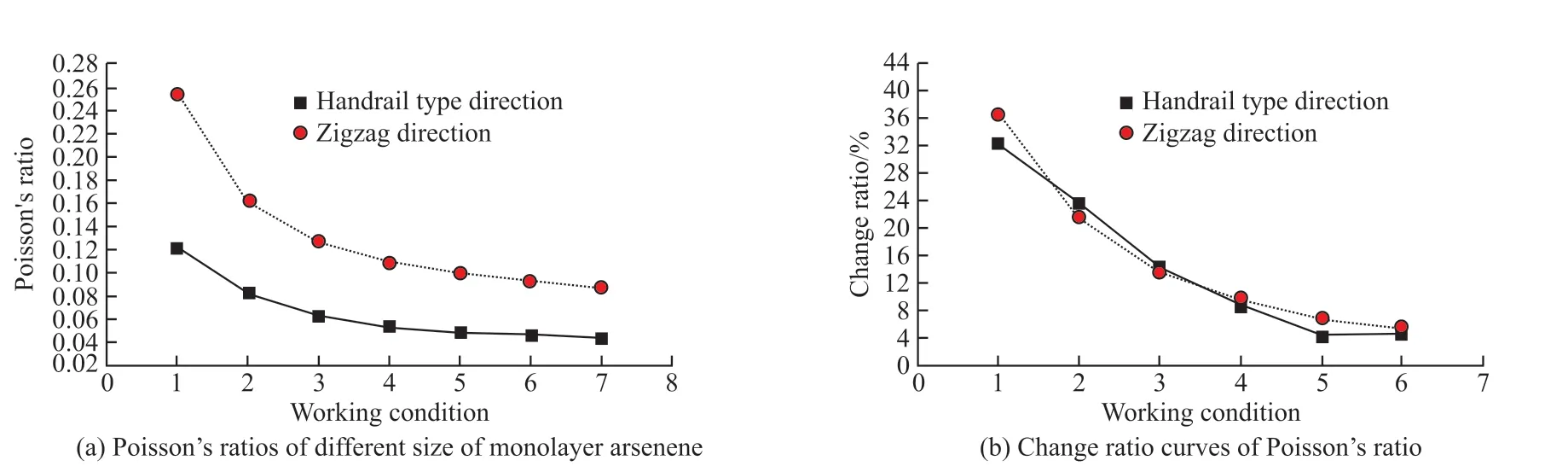

It can be seen from the Poisson’s ratio results of the seven working conditions in Fig.5(a) that with the increase of the size, the Poisson’s ratio of the monolayer arsenene in the handrail and zigzag directions decreases monotonically, indicating that the Poisson’s ratio of the monolayer arsenene is also negatively correlated with the dimension.When the size is large enough, the Poisson's ratio of arsenene in both directions tends to be stable, indicating that the effect of large size on the Poisson's ratio of arsenene is weakened.

Fig.5 Change and change ratio curves of Poisson’s ratio of monolayer arsenene

From the variation of Poisson’s ratio with different sizes of monolayer arsenene (Fig.5(a)), as the size increases, the Poisson's ratios in both directions of the monolayer arsenene show a decreasing trend.This is consistent with the conclusion calculated by Chenet al[34]using density functional theory that the Poisson's ratio of arsenene decreases with increasing size in both the handrail and zigzag directions.In the calculation model of the same dimension, the Poisson's ratio value of the handrail-shaped direction of arsenene is always smaller than that of the zigzag-shaped direction, indicating that the Poisson's ratio of monolayer arsenene is also related to the direction.This conclusion is consistent with Literature[34].Due to the difference in the Poisson's ratio of arsenene in the two directions, it can be seen that the size change has a more significant effect on the Poisson's ratio of arsenene in the zigzag direction than in the handrail direction, and also has an effect on the Poisson's ratio in the handrail direction,but this effect has been weakened.From the change ratio curves of Poisson's ratio (Fig.5(b)),the change ratio of Poisson's ratio in the handrail and zigzag directions of monolayer arsenene is gradually decreasing in general, but in the process of decreasing, the handrail direction fluctuates slightly, indicating that the Poisson's ratio of arsenene with small size is more sensitive to size change, and the effect of size change on the Poisson's ratio of arsenene with large size is not obvious.

3.3 Shear modulus

From the shear modulus results of the seven working conditions in Fig.6(a), it can be seen intuitively that the shear modulus of monolayer arsenene in the zigzag direction decreases with the increase of the size, and the shear modulus in the handrail direction increases with the increase of size; The shear modulus of monolayer arsenene in different directions is related to dimension, and the variation trend is monotonic, but the correlation is different.The zigzag direction is still negatively correlated, and the handrail direction is positive.This is consistent with the conclusion that Guoet al[32]predicted the anisotropy of the shear modulus by calculating the shear modulus of the monolayer arsenene.

Fig.6 Change and change ratio curves of shear modulus of monolayer arsenene

From the variation of shear modulus of monolayer arsenene with different sizes (Fig.6(a)), it can be seen that with the increase of size, the shear modulus of monolayer arsenene in both the handrail and zigzag directions is monotonic.In the calculation model of the same dimension, the shear modulus value of the monolayer arsenene in the zigzag direction is always smaller than that in the handrail direction, the change trend of the handrail direction fluctuates greatly, and the change trend of the zigzag direction is relatively gentle.The shear modulus is also direction dependent,and size changes have a more significant effect on the shear modulus of the handrail direction than the zigzag direction.From the change ratio curves of shear modulus (Fig.6(b)), the change ratio curve of monolayer arsenene in the zigzag direction is gradually decreasing,but the change ratio curve in the handrail direction is increasing greatly, and both of them gradually tend to be flat, indicating that the shear modulus of arsenene in different directions has different sensitivity to size changes.Compared with the zigzag direction, the shear modulus in the handrail direction is more sensitive to size change.

4 Conclusions

a) The Young's modulus of monolayer arsenene is related to both dimension and orientation.As the size increases, the Young's modulus decreases gradually.In the case of the same dimension, the Young's modulus value in the handrail direction is always higher than that in the zigzag direction.It can be seen that the size change has a greater impact on the Young's modulus of the monolayer arsenene handrail direction, and the zigzag direction has a very small change and has a small impact.

b) The Poisson's ratio of monolayer arsenene is also related to both dimension and orientation.As the size increases, the Poisson's ratio decreases gradually.In the case of the same dimension, the Poisson's ratio value of the handrail direction is always lower than that of the zigzag direction.It can be seen that the size change has a greater effect on the Poisson's ratio of the zigzag direction of the monolayer arsenene, and the effect on the handrail direction is weakened.

c) The shear modulus of monolayer arsenene is also related to both dimension and orientation.As the size increases, the shear modulus of the zigzag direction gradually decreases, and the change range is small,and the handrail direction gradually increases, and the change range is large.In the case of the same dimension, the shear modulus value in the zigzag direction is always smaller than that in the handrail direction.It can be seen that the size change has a more significant effect on the shear modulus of the monolayer arsenene handrail direction, and the effect on the zigzag direction is not obvious.

Based on the above conclusions, the relationship between the mechanical properties of monolayer arsenene and its size and orientation is studied in this paper.The finite element simulation results are in good agreement with the prediction results of the DFT theoretical method.At present, there are relatively few works on the effect of size and orientation on the mechanical properties of arsenene using the finite element method.Therefore, it provides reference data for further research and development in this field.

Conflict of interest

All authors declare that there are no competing interests.

Journal of Wuhan University of Technology(Materials Science Edition)2024年1期

Journal of Wuhan University of Technology(Materials Science Edition)2024年1期

- Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- One-pot Synthesis of Hierarchical Flower-like WS2 Microspheres as Anode Materials for Lithium-ion Batteries

- Controllable Synthesis of Au NRs and Its Flexible SERS Optical Fiber Probe with High Sensitivity

- Effciient Direct Decomposition of NO over La0.8A0.2NiO3(A=K, Ba, Y) Catalysts under Microwave Irradiation

- Appreciable Enhancement of Photocatalytic Performance for N-doped SrMoO4via the Vapor-thermal Method

- Infulence of Current Density on the Photocatalytic Activity of Nd:TiO2Coatings

- The Negative Thermal Expansion Property of NdMnO3 Based on Pores Effect and Phase Transition