Rice Husk at a Glance:From Agro-Industrial to Modern Applications

Masoumeh Kordi, Naser Farrokhi, Martin I. Pech-Canul, Asadollah Ahmadikhah

Review

Rice Husk at a Glance:From Agro-Industrial to Modern Applications

Masoumeh Kordi1, Naser Farrokhi1, Martin I. Pech-Canul2, Asadollah Ahmadikhah1

(Department of Cell & Molecular Biology, Faculty of Life Sciences and Biotechnology, Shahid Beheshti University, Tehran 1983969411, Iran; 1062 Metallurgical Industry Avenue, Industrial Park Saltillo-Ramos Arizpe, Ramos Arizpe, Coahuila 25900, Mexico)

Excessive waste production has led to the concept of a circular bioeconomy to deliver valuable by-products and improve environmental sustainability. The annual worldwide rice production accounts for more than 750 million tons of grain and 150 million tons of husk. Rice husk (RH) contains valuable biomaterials with extensive applications in various fields. The proportions of each component depend primarily on rice genotype, soil chemistry, and climatic conditions. RH and its derivatives, including ash, biochar, hydrochar, and activated carbon have been placed foreground of applications in agriculture and other industries. While the investigation on RH’s compositions, microstructures, and by-products has been done copiously, owing to its unique features, it is still an open-ended area with enormous scope for innovation, research, and technology. Here, we reviewed the latest applications of RH and its derivatives, including fuel and other energy resources, construction materials, pharmacy, medicine, and nanobiotechnology to keep this versatile biomaterial in the spotlight.

circular bioeconomy; rice husk activated carbon; rice husk ash; rice husk biochar; rice husk hydrochar; rice husk application

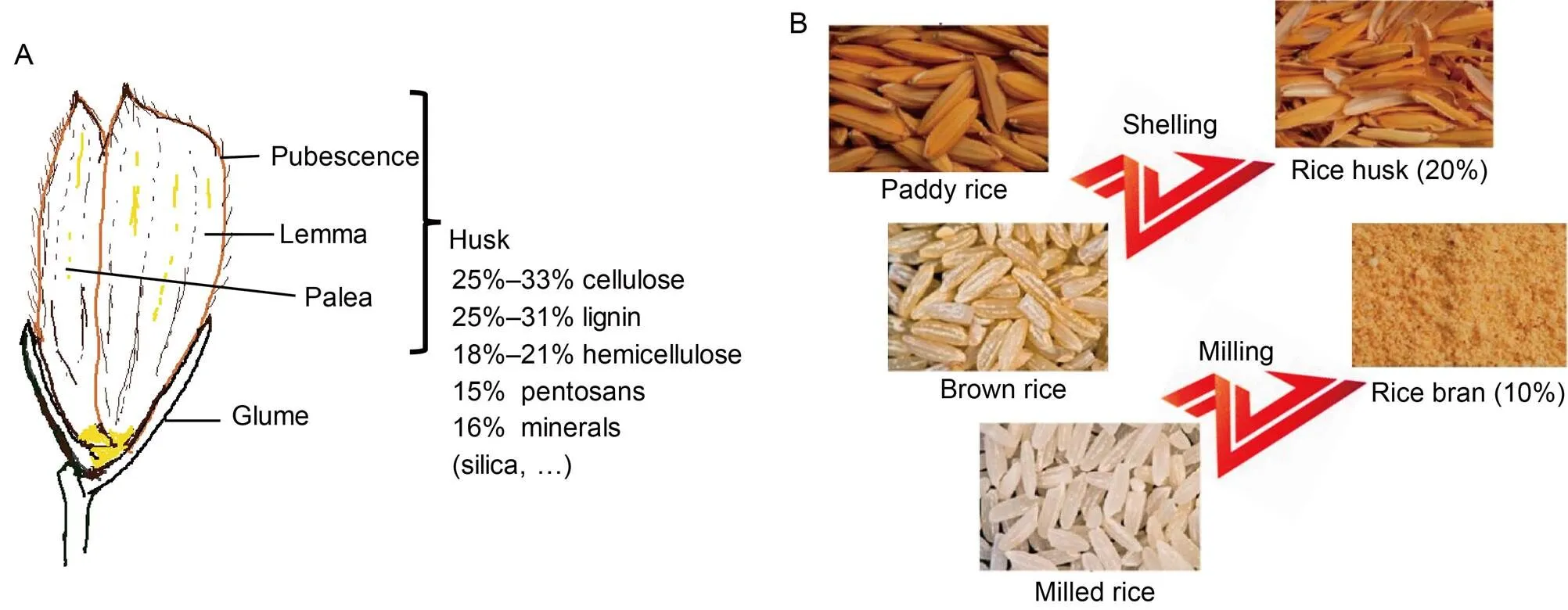

A bio-based circular economy leads to a sustainable future, tampering with the effects of environmental changes, including global warming. Biomass recycling boosts the economy and promises better use for agricultural wastes (Muscat et al, 2021; Gursel et al, 2022; Mujtaba et al, 2023). Rice husk (RH)(Fig.1-A) is one of the primary agricultural wastes produced in rice-cultivating countries. Despite its numerousapplications, its economic benefits and contributionshave not been sufficiently highlighted (Prabhakaran et al, 2017; Bodie et al, 2019). Two key functions of RH are providing mechanical protection to rice filling and preventing water loss from brown rice grains, while also blocking ultraviolet light, ensuring the smooth development of rice grains (Fu et al, 2015). RH is essential for grain development and the husk can hinder grain filling (Fu et al, 2015). RH is a by-product of rice grains during the shelling and milling processes (Fig. 1-B), in which white and polished grains without husk and bran are produced (Prabhakaran et al, 2017; Bodie et al, 2019). Following harvest, rice grains are dried, ground, and peeled. Rice milling can be carried out using two traditional or mechanical methods:the traditional method with mortar and pestle or hand stone (Dhankhar, 2014; Bodie et al, 2019),while the mechanical method employs various industrial mill types, such as hullers, sheller-hullers orsheller- cone polishers (Dhankhar, 2014; Bodie et al, 2019). RH can be further processed to produce ash (RHA), biochar (RHB), hydrochar (RHH), and activated carbon (RHAC).

As a complex hierarchical assembly, RH accounts for approximately 20% of rice weight (Kumar et al, 2013). Energy dispersive X-ray analysis of the outer/ inner surface of RH reveals its elemental constituents as 9.55%?18.74% carbon, 30.90%?35.51% oxygen, 58.19%?43.17% silica, and 1.36%?1.66% potassium by weight (Kolar and Jin, 2019). Additionally, RH consists of hollow fibers composed of cellulose (25%?33%), lignin (25%?31%), and hemicellulose (18%?21%) with lower amounts of pentosans (15%) and minerals, including silica (16%) (Gao et al, 2018; Chen et al, 2020) (Fig. 1-A). As silica plays an important role in defining RH and its derivatives, as well as corresponding applications, it is discussed in more detail.

Fig. 1. Rice grain constituents (A) and grain processing (B).

Silica is a common oxide form of silicon (Si), which is called phytoliths (non-crystalline silicon dioxide) in the remains of living organisms. It participates in various processes, such as silicate weathering, soil formation, biota nutrition, and atmospheric CO2regulation (Li et al, 2014; Shen et al, 2014; Debona et al, 2017; Rea et al, 2022). Dissolved Si (H4SiO4) is easily absorbed from the soil to improve plant tolerance before environmental stress, such as lodging resistance (Liang et al, 2015; Mahmad-Toher et al, 2022). Rice absorbs and accumulates silicic acid to form Si in its tissues like the xylem (Sun et al, 2019; Chaiwong et al, 2022; Mahmad-Toher et al, 2022) and transpiration sites (e.g., cell walls, cell lumina, and intercellular spaces). In these tissues, silica is polymerized and hydrated to become amorphous phytoliths, which vary in amounts among rice genotypes (Li et al, 2014; Sun et al, 2019; Mahmad-Toher et al, 2022; Puppe et al, 2022). The variations of silica amount in different rice tissues and the elemental compositions (Si, Al, Fe, and C) of phytoliths are all genotypically dependent (Li et al, 2014). Among rice tissues, RH contains the highest amount of silica and the grain has the lowest (Liang et al, 2015; Mahmad-Toher et al, 2022).

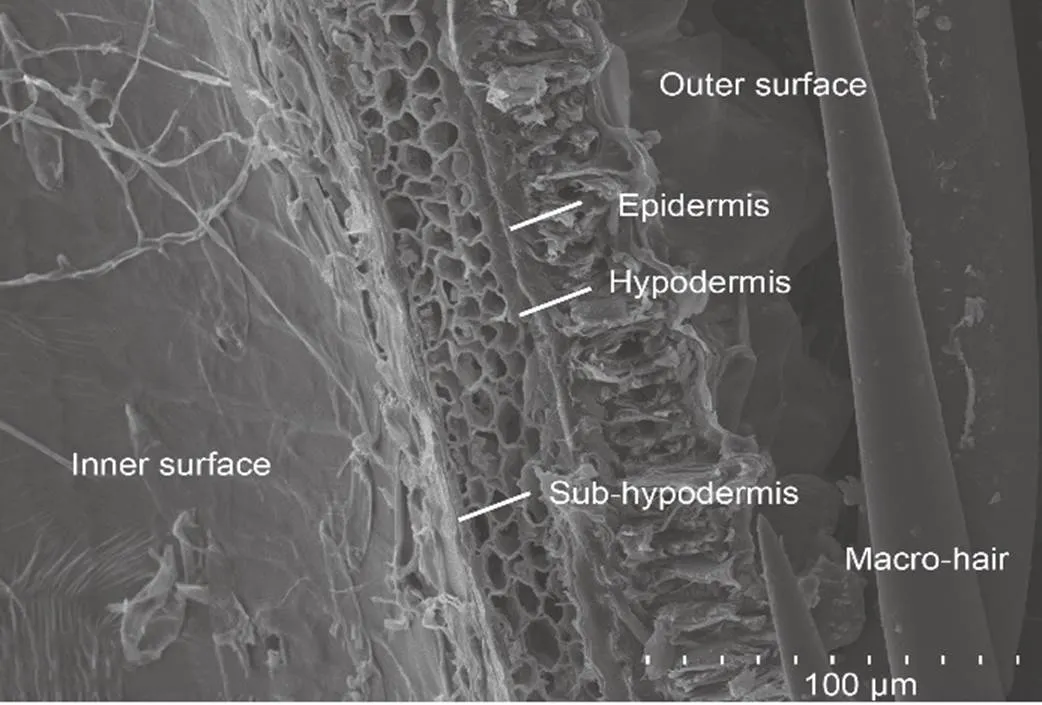

Structurally, RH consists of the epidermis, sub- hypodermis, and hypodermis. The thickness of these layers and cell walls, the diameter of the hollow fibers, and tensile properties are different depending on the genotypic variations of rice (Bisht et al, 2020; Chen et al, 2020; Hoerudin et al, 2022). Scanning electron micrographs taken from RH cross sections are indicative of the layers, sometimes covered with macro-hairs on the epidermal surface (Fig. 2). The hypodermis, between a row of large cells of the epidermis and 3?4 rows of sub-hypodermis, is oriented perpendicular to these layers (Fig. 2).

To illustrate the differences between the outer and inner surfaces of RH in terms of shell size, surface morphology, macro-hair, shape of protrusions, and spacing of protrusions, 10 rice genotypes with totally different appearances were chosen and photographs were taken by a scanning electron microscope to illustrate the differences (Fig. 3-A to -J). Although the outer layer patterns appear similar, their sizes are different, and they are covered with different numbers of macro-hairs, the lengths of which also vary, and the protrusions on the surface are more pronounced in some genotypes. The inner surface of the RH in different genotypes has a smooth exterior, examples of which are shown in Fig. 3-K and -L.

Fig. 2. Scanning electron micrograph of cross section of rice husk.

Outer surface, inner surface, macro-hair, epidermis, hypodermis, and sub-hypodermis are shown.

RH can be used as the bed and energy source in solid-state fermentation, an environment with very little water (Soccol et al, 2017; Kaniapan et al, 2022; Kadam et al, 2023), to proliferate microorganisms for agro-industrial applications (Nighojkar et al, 2019) (Fig. 4-A). It is also used as fuel for boilers, electricity and steam generation, animal feed, and paper and board production (Kalderis et al, 2008; Kaniapan et al, 2022). RH is used as a substrate in broiler farms (Chaitanoo et al, 2021). RH has applications in environmental sustainability by removing various dyes, organic or inorganic pollutants such as metal ions, phenols, pesticides, and atmospheric contaminants (Chen et al, 2011; Yang et al, 2022).

RHA is produced via burning RH to produce silica (Putranto et al, 2021; Aprilia et al, 2023). Amorphous silica is a suitable alternative to conventional silica (obtained from quartz). It can be used to produce ceramic materials, glass, refractory, and silica aerogel composites (Bahrami et al, 2017; Soltani et al, 2017; Hossain and Roy, 2019). RHA can be used as a source of silica for both Portland cement and alkali-activated based concrete (Kim et al, 2014) (Fig. 4-B). Silica obtained from RH can be used to manufacture masks made from silver nanocluster and silica. Such masks can efficiently reduce SARS-CoV-2 infection to zero (Prabha et al, 2021).

RHB is obtained by burning RH under limited oxygen conditions at relatively low temperatures (< 700 oC) (Zhang X G et al, 2020). The application of RHB has been shown to increase the bioavailability of soil nutrients, suppress N2O release, enhance nitrogen uptake, and reduce soil surface bulk density in agronomic studies (Tan et al, 2018; Phuong et al, 2020).RHB also causes moderate soil acidity, facilitating the successful uptake of heavy metals such as Ba, Pb, Cu, As, and Zn by crops (Campos et al, 2021). For example, the use of KOH-enhanced biochar for soil Cd and Pb stabilization revealed that biochar pyrolyzed at 300 oC possesses more oxygen-containing functional groups, and KOH modification can clear impurities and improve pore structures (Wang et al, 2020). In apple orchard, the application of a mixture of RHB and organic fertilizer increases soil organic carbon content and bacterial diversity (Duan et al, 2021).

Fig. 3. Scanning electron microscope images taken from rice husk outer (A?J) and inner (K and L) surfaces of 10 rice genotypes.

A, ARC 7229 (India); B, JAMIR (Bangladesh); C, BUL ZO (South Korea); D, DOBLE CAROLINA RINALDO BARSANI (Uruguay); E, DAWEBYAN (Myanmar); F, RATHUWEE (Sri Lanka); G, MELANOTRIX (Tajikistan); H, FORTUNA (the United States); I, BLACK GORA (India); J, SRI MALAYSIA DUA (Malaysia); K, ARC 7229 (India); L, DAWEBYAN (Myanmar). Genotypes used in these photographs were obtained from the International Rice Research Institute. A wide diversity of surface protrusions and macro-hairs are evident and inner surfaces of rice husk have a relatively smooth exterior (K and L). The magnifications are indicated on the edge of each photograph (A?J, 300 μm; K, 50 μm; and L, 100 μm).

Fig. 4. Rich husk and its derivatives (A), as well as their applications (B).

RHH is generated in an aqueous environment at lower temperatures, ranging from 180 oC to 350 oC (Li et al, 2020; Li et al, 2021), and it is stored for longer period of times (2?16 h) compared with biochar (Kalderis et al, 2014; Nizamuddin et al, 2019) (Fig. 4-A). RHH has promising effects in fuel cells, soil fertility improvement, and the immobilization of soil heavy metal cations and anions (Nizamuddin et al, 2018; Teng et al, 2020). For instance, a bioretention column filled with FeCl3-modified RHH can diminish nitrogen pollution in runoff (Smith et al, 2020; Wang et al, 2021). RHH has also been used as an adsorbent; however, it is less stable and less effective in adsorbing non-polar organic matter (Nizamuddin et al, 2019). The use of RHB and RHH as fillers in the synthesis of polymer composites has recently received much attention, especially for the remediation of environmental pollutants in both aquatic and atmospheric systems (Bahrami et al, 2015a; Nizamuddin et al, 2019; Zhang X G, et al, 2020).

RHAC is obtained from RH in a two-step procedure: carbonization and activation (Cheenmatchaya and Kungwankunakorn, 2014). In carbonization, raw carbonaceous materials such as RH are carbonized at temperatures between 200 oC and 400 oC for 1 h in an inert muffle furnace to produce charcoal. The resultant substance is typically chemically activated by H3PO4(Cheenmatchaya and Kungwankunakorn, 2014). Pyrolysis, the thermochemical decomposition of organic matter such as RH into non-condensable gases, condensable liquids, and solid residues, has also been used in RHAC production (Basu, 2018; Pang, 2019; Zhan et al, 2019). RHAC is a cost-effective adsorbent used in environmental protection, water, and wastewater treatment as well as gas filters (Chen et al, 2011). The carbon adsorption capacity depends on factors such as the raw material, the history of its preparation, and treatment conditions including pyrolysis temperature and activation time (Crini, 2006). RHAC possess a high conductivity potential and can be prepared as a double layer, making it suitable for use as electrode materials in electric double layer capacitors (Chen et al, 2011). RH and its ingredients (such as silica) or derivatives are used in agriculture and various industries (Fig. 4-B). Here, we discuss the latest findings on RH applications and their prospects.

Agricultural industry

Biological control agents

A paradigm shift in the use of chemical pesticides, which has many health and environmental side effects, towards the usage of more biocontrol agents has led to looking for cheaper substrates to produce these agents. Fungal entomopathogens are a preferred method for suppressing most pests and their larvae (Lacey et al, 2015; Asadi et al, 2021). Fungal biopesticides, such asand, are produced using a solid-state fermentation setup that contains RH (Sala et al, 2020, 2021). Similarly, a porous terracotta disc embedded with RH nanoparticles (AgNPs-RH) has been designed to control insect larvae efficiently (Sundaramahalingam et al, 2020). In a study, the antibacterial activity of RH loaded with silver nanoparticles was found to be twice as effective compared with using pure Ag particles alone. This is because RH-Ag composites have a high BET (Brunauer-Emmett-Teller)-specific surface area (explains the physical adsorption of gas molecules on a solid surface) of 1996 m2/g, which results in a strong bacterial adsorption capacity. This enhanced adsorption capacity is related to the higher adsorption of RH and its potential for the slow release of silver ions (Cui et al, 2015). In addition to being an excellent substrate for solid-state fermentation culture, RH can also be used as a biocarrier in the commercial formulation of pesticides, improving dispersion, solubility, and wettability (Nair and Sawant, 2006).

Soil fertilization and soil improvement

Proper processing of RH can benefit soil due to the bioavailability of silica in rice paddy fields, which affects crop growth and development (Badar and Qureshi, 2014; Sekifuji and Tateda, 2019). RH has been used in composting (Thiyageshwari et al, 2018). For instance, the combination of RH compost, RHB and mycorrhiza onshows its remediation effect in removing the added antibiotic sulfadiazine from greenhouse soil (Ahmadabadi et al, 2019). RHB andapplications have shown their impact on rice productivity in a genotype- dependent manner (Win et al, 2019). The use of RHB and RHAC on bacterial cultures has been shown to positively impact the growth, sporulation, and antifungal activity ofsp(Ebe et al, 2019). RH has also been used as an absorbent to remove harmful hormonal substances, estrone, β-estradiol, estriol, and antibiotics present in manure that should not be present in fertilizers (Wan Ismail and Umairah Mokhtar, 2020).

Soils are usually poor in organic matter. Biofertilizers are cost-effective, environmentally friendly, and a renewable source of nutrients in a sustainable agricultural system (Maki et al, 2012). Composted RH can be returned to the soil to protect and improve soil organic matter, increase agricultural productivity, and lessen chemical inputs (Thiyageshwari et al, 2018). Worms can use RH and other rice residues to produce vermicompost (Shak et al, 2014). RH and RHB have also been used as microbial carriers in combination with organic and mineral fertilizers, effectively improving soil quality, microbial diversity, and nitrogen uptake by plants (Tan et al, 2018; Duan et al, 2021).

Mushroom substrates

Mushroom cultivation is a suitable bioconversion process for crop residue management. Saprophytic fungi naturally grow on rotten wood, tree trunks, decaying organic matter, and soil rich in moist organic matter (Tsegaye and Tefera, 2017). The cultivation of mushrooms on agricultural residues serves as an environmental protection method. The conversion of inedible biomass residues into nutritional proteins in the form of fungi is of great importance (Tsegaye and Tefera, 2017). In commercial mushroom production, casings containing sawdust and RH are used as substrates to provide moisture and proper conditions for the initial growth of mushrooms, thereby improving quality and yield (Anyakorah and Dike, 2013).For example, the oyster mushroomis an edible fungus that can grow on agricultural wastes (Frimpong-Manso et al, 2011; Anyakorah and Dike, 2013).

Mulching

Mulch is a spreadable substance applied to the soil to minimize water evaporation, prevent soil erosion, inhibit weed growth, slow down the release of nitrogen for plant uptake, and improve the physical, biological (soil microbiota), and chemical properties of the soil, thereby increasing productivity (Humphreys et al, 2016; Lalruatsangi et al, 2018; Adnan et al, 2020). When RH is used as mulch alone or combined with sawdust or paddy straw, it can maintain soil moisture, regulate soil temperature, preserve soil organic matter, improve soil structure, and prevent soil erosion, ultimately generating a proper micro- environment for the development of soil microbiota and improving crop yields (Lalruatsangi et al, 2018).

Food and feed industry

Aflatoxins, carcinogenic metabolites, are produced by thefungus, which enters the food chain (Ansari et al, 2021). RH has shown a promising absorptive function toward aflatoxins (Scaglioni and Badiale-Furlong, 2016). Further studies have demonstrated the potential of magnetic mesoporous silica from RH in removing this food contaminant from edible oil (Li et al, 2020). RH is an excellent alternative to expensive peanut protein in the rabbit diet as a source of fiber, and it has anti-aflatoxin properties with high economic efficiency (Adeniji et al, 2014; El-Sanhoury, 2018).

Due to its constituents, including silica and lignin, RH has low nutritional value and is not suitable for ruminant feed (Bhullar and Gruissem, 2013; Abazari et al, 2016). However, it has beneficial effects as insoluble fibers for developing gut microbiota and can be used as a bulk feeder in poultry and broiler farms (Abazari et al, 2016). RH processing via fermentation and chemical treatment leads to high nitrogen content and improves digestibility (Vadiveloo et al, 2009). It can be used as a nutrient substitute for wheat bran in ruminants (Naseer et al, 2017). The effective use of RHB has been reported in aquaponic (hydroponic + aquaculture) systems for water treatment, increased mass oxygen transfer in water, and greater growth rates of fish and plants (Mopoung et al, 2020). RHAC has also been used in the feed of fish trevally giant (), with a significant effect on the daily and absolute growth rate, feed conversion ratio and efficiency, survival rate, gastric cavity length, and villous intestine length and width (Firdus et al, 2020).

Environmental application

Developing environmentally friendly and sustainable materials enable the reuse of wastes has a significant bearing on the economy (Samaddar et al, 2018). Crop residues are one of the largest sources of biomass globally that, up to recent years, are often neglected and discarded or burned for energy recovery, posing a significant threat to the environment. RH is an excellentenvironmental absorbent for removing various pollutants, including xenobiotics from industrial zones, contaminated soil and water (Shamsollahi and Partovinia, 2019).

Soil remediation

Surface soils inherently bear heavy metals or become contaminated by industrial effluents, air pollution and/ or pesticides drift from neighboring farms. Environmentalpollution with metals reduces the fertility of agricultural soils, decreases crop yield, and affects the human food chain (Wei and Yang, 2010). Due to the high lignin and cellulose contents in RH, which decompose easily, it is not effective to directly apply RH to soils (Rosa et al, 2012). RH carbonization in the absence of oxygen produces charcoal and vinegar. RH charcoal increases the concentrations of Ca, Mg, K, and Si in soils as well as soil pH. Long-term application of RH charcoal has shown a beneficial effect on soil fertility by removing salinity (Chien et al, 2011; Phuong et al, 2019, 2020). RH has been used as a fungal growth enhancer, for example in the case of, for bioremediation purposes (Shuib et al, 2016). RH and RHB in combination withand soybean have been used for phytoremediation (Li et al, 2019). Soil contamination with Pb, a non-degradable and carcinogenic metal, is a serious global concern that negatively impacts healthy crop production (Laidlaw et al, 2017). RH is a good adsorbent for removing Cu, Fe, and Zn from soils (Chockalingam and Subramanian, 2006). RHB and RHA can improve the properties of metal-contaminated soils (Kiran and Prasad, 2019) and increase plant growth parameters by enhancing nutrient intake and antioxidant enzymatic activities (Wisetkomolmat et al, 2023). The application of RHA to soils reduces Pb concentration inroots by 87% compared with control plants (Kiran and Prasad, 2019). Immobilization and removal of contamination by heavy metals from soils have been achieved using RHB alone (Derakhshan-Nejad and Jung, 2019; Wang et al, 2019), surface-modified RHB by iron oxide (Cope et al, 2014), sulfur-modified RHB (O’Connor et al, 2018), RHB + zeolite (Zheng et al, 2020), and KOH-treated RHB (Wang et al, 2020). Soil Cr contamination is an important environmental issue. The use of zerovalent iron nanoparticles supported by RHB as a modifier manages to minimize Cr contamination in soils (Liu et al, 2020). The bioremediation effect of RHB in heavy metal immobilization in soil is depend on its production conditions. Shi et al (2019) demonstrated that RHB produced at higher temperatures (500 oC and 700 oC) has less functional groups and greater remediation activity. Furthermore, RHB is effective in adsorbing water contaminants in oil (Kandanelli et al, 2018). β-cyclodextrin-functionalized RH has been shown to act as a remediator for heavy metals and organic pollutants such as pesticides in a pH-dependent or independent manner (Qu et al, 2020).

RH has also been used as a carrier for the herbicide 2,4-D (2,4-dichlorophenoxyacetic acid), facilitating herbicide diffusion (Abigail et al, 2016).Biochar made from RH and palm oil empty fruit bunch is able to improve soils contaminated with herbicides (Yavari et al, 2019). The use of RHA in combination with cow dung can remove glyphosate, a widely-applied herbicide in crop agronomy, from water (Garba et al, 2019). RHA and RHB have also been used in the absorption of other herbicides/pesticides and other chemicals such as paraquat, 4-chloro-2-methylphenoxyacetic acid,metolachlor, atrazine, imidacloprid, and fenoxaprop- ethyl (Rongchapo et al, 2013; Deokar et al, 2016;Mandal et al, 2017; Amiri et al, 2018; Jing et al, 2018).

Water refining industry

Effluents from various industries, such as agriculture (pesticides and herbicides), textiles, leather, cosmetics, pharmacy, and food, contain undesirable biological and chemical compounds. In cases where these effluents end up in open seas, they can endanger aquatic life (Swarnalakshmi et al, 2018). The most critical drugs entering the water are antibiotics, painkillers, and hormonal drugs (Balarak et al, 2020). They enter the water via the sewage systems of drug factories, hospitals, and households (Balarak et al, 2016). Antibiotics remain essentially unchanged in both aquatic and terrestrial environments, which have emerged as an environmental problem in recent years (Balarak and Mostafapour, 2019). Research has shown that RHB is effective in removing antibiotics such as levofloxacin and tetracycline from aqueous solutions (Yi et al, 2016; Bushra and Remya, 2020). RH modified by 3-amino-propyl triethoxysilane is able to remove scandium from wastewater (Salman et al, 2020). Betiha et al (2020) demonstrated that a mesoporous silica- polymer hybrid produced from polyvinylpyrrolidone and RH can absorb divalent heavy metals from wastewater. Additionally, RHB effectively removes 2,4-D from agricultural drainage water (Amiri et al, 2018).

Nitrate pollution in water is a widespread problem. The purification of nitrate from water by biosorption is a promising approach for nitrate removal (Dey et al, 2021). RH, as a biosorbent, has been used to remove nitrate ions from water (Afjeh et al, 2020).

As an effective drug absorbent, RHA has also been used for the removal of contaminants such as acid orange 7, amoxicillin, metformin, and carbamazepine (Swarnalakshmi et al, 2018). Standard methods of removing heavy metals from industrial wastewater include reverse osmosis, electromechanical reduction, chemical precipitation, ion exchange, and membrane filtration, which are often very expensive (Pérez-Marín et al, 2008). The absorption capacity of agricultural wastes, due to their high porosity and consequent large surface area for heavy metals, is significantly high (Nguyen et al, 2013). RH has proven to be efficient in removing heavy metals (Mn, Ni, and Cr) from water (Batagarawa and Ajibola, 2019).

Dye removal

RHB and RHAC have adsorption capabilities for removing chemicals from industrial effluents (Prapagdee et al, 2016). The toxicity of many dye variants, with some being mutagenic and disease causing agents, prompts the need for removal from the environment (Chowdhury et al, 2011). Methods for removing dyes include biological oxidation, chemical deposition, and adsorption of dyes with adsorbents (Vadivelan and Kumar, 2005). RH and RHB have been used to remove color compounds such as methylene blue from aqueous solutions (Vaz et al, 2017; Darabi et al, 2018).

Composite production

Due to its unique characteristics, RH has the potential to be used in developing bio-composites to reinforce already commercialized composites (Majeed et al, 2017; Suhot et al, 2021). Since the 1970s, RH has been used as a filler with various matrix materials to create hybrid composites such as polypropylene, polyethylene, resins, and natural rubber (Bisht et al, 2020). The use of polymer composites reinforced with natural fibers promises high specific strength and modulus, economic viability, less density, biodegradability, environmentally friendly, low cost, reduced tool wear, and enhanced energy recovery over traditional metallic alloys. Therefore, they have been implemented both in industry and fundamental research (Arjmandi et al, 2015; Hemnath et al, 2021). For instance, natural composites made from sugarcane bagasse fiber and RH show good mechanical properties such as tensile and flexural strength. It was found that the addition of RH filler improves the mechanical properties by reducing the void content in the composites (Hemnath et al, 2021). RH, in combination with wood particles and other materials, can be used in the production of panelboards (Chalapud et al, 2020; Akinyemi et al, 2022) and other building and construction materials (Arjmandi et al, 2015).

Biofuel production

Given the rapid increase in worldwide energy demand, a growth of about 30% is projected by 2040 (OECD, 2016). Accordingly, substantial efforts have been made to replace fossil fuels with more sustainable renewable energy sources, such as agricultural wastes (Ge et al, 2016; Biswas et al, 2017). Combustion technology has been proven to have value in utilizing RH. RH features a three-dimensional network structure composed of organic carbon and silica, which can be used to produce activated carbon, silica, syngas, and biofuel (Soltani et al, 2015; Bernardo et al, 2017; Wang et al, 2018). Although not absolutely sustainable, RH can serve as a coal replacement with fewer pollutants (Nayak et al, 2017).

Anaerobic digestion of organic matter (from plants and animals) by bacteria produces biogas, which in the process of digestion, produces both energy (in the form of gas) and valuable soil products (in the form of liquid and solid). Biogas contains 50%?70% methane, 30%?40% carbon dioxide, and small amounts of other gases (Gopal et al, 2019). Biogas can be obtained from lignin-rich materials such as RH in a reactor (Koskin et al 2020; Rea?o, 2020). Gasification of RH to produce syngas has become a topic of interest in recent years (Bernardo et al, 2017).

Hydrogen produced from water using renewable energy sources is referred to as green hydrogen (Ota et al, 2014).RH can be used to produce green biohydrogen (Rea?o, 2020), and used as a second-generation fermentative resource in bioethanol production due to its ability to deliver fermentable sugars such as glucose, xylose, arabinose, galactose, and mannose (Kaur and Singh 2017; Tabata et al, 2017). RH is a suitable raw material for power plants, as it outperforms fossil fuels in terms of environmental emissions (Chungsangunsit et al, 2005).

Other energy resources

RH nanostructures have been employed in modern energy fields such as Li-ion batteries, supercapacitors, solar cells, and triboelectric nanogenerators (Wang et al, 2018). RH is used to create cost-effective carbon, an effective additive for Li-ion batteries (Zhang Y et al, 2020). RH silica can be converted into high-purity Si to form uniform nanoporous silicon nanostructures that exhibit excellent performance as Li-ion battery anodes (Cho et al, 2016). RH is also used to produce carbonaceous materials such as graphene oxide, which has applications in electronics, energy generation, biomaterials, and environmental remediation (Manpetch et al, 2022). Carbon electrode-active materials derived from RH are being used to fabricate supercapacitor electrodes (for energy storage applications) (Cai et al, 2020). RHA has been utilized to produce a more affordable and environmentally friendly source of Si that can be used in solar cells to absorb sunlight (Putranto et al, 2021).

Construction materials

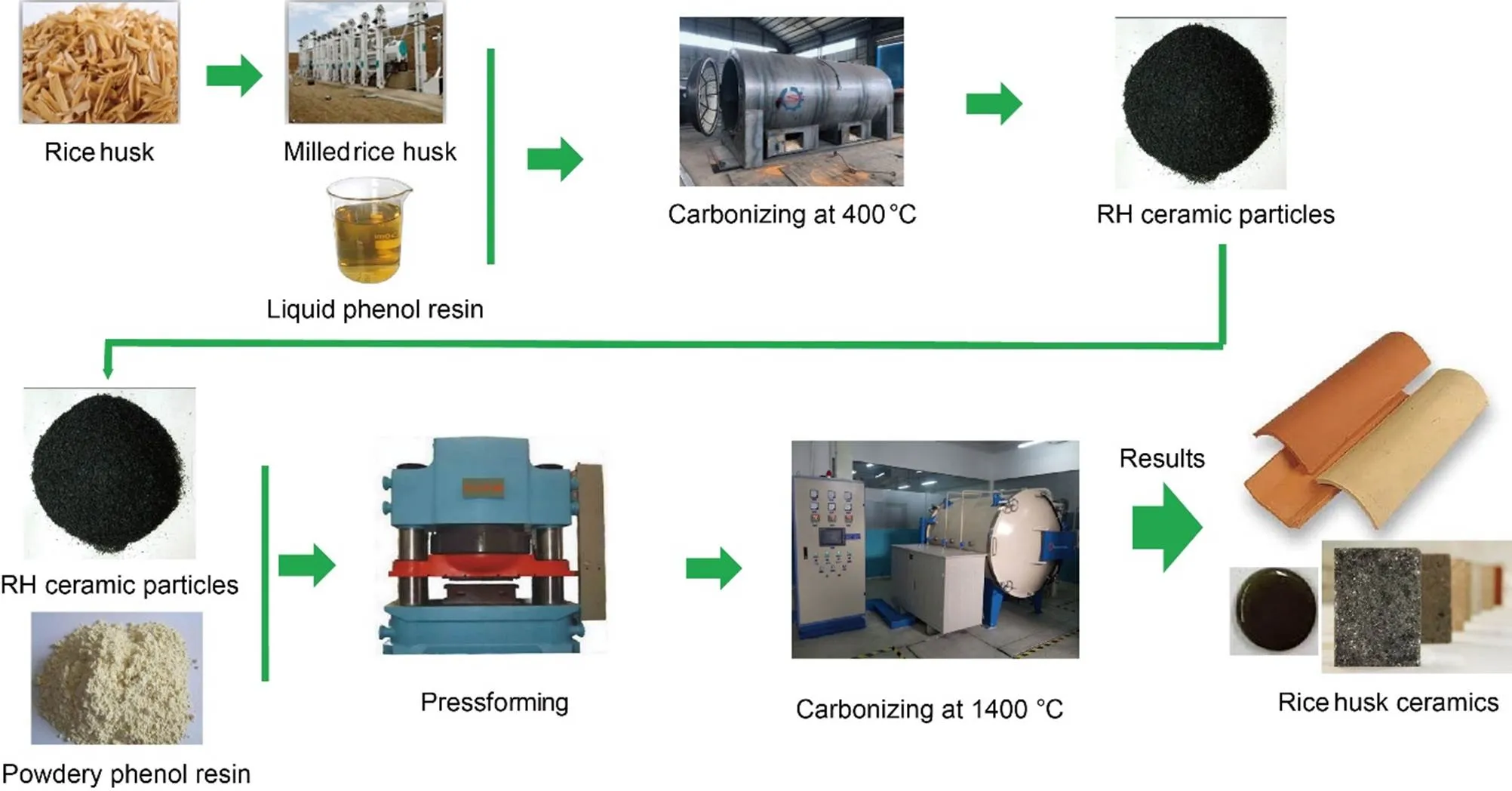

Ceramics

RH and RHA have been used in the production of ceramics. For example, a porous ceramic is made from a composite of alumina and RHA (Ali et al, 2017). The process of producing ceramics from RH is as follows (Fig. 5): milling, combining RH with liquid phenol resin in a ratio of 3:1, drying at 150 oC?180 oC, carbonization, crushing the carbonized mixture, pressing the crushed mixture with powdery phenol resin to make a disc, re-carbonization of the discs and finally cooling the ceramic discs (Shibata et al, 2014). In the ceramic industry, silica is the backbone (Carter and Norton, 2007). Manufacturers use silica sand, gravel, sandstone, granite, quartz, and quartzite as the source. RH is rich in silica, which can be used in the ceramic industry, allowing natural resources to remain safe and sound (Hossain et al, 2018). RHA has been used for the synthesis of cement mortar (Chatveera and Lertwattanaruk, 2014) and glass-ceramics (Danewalia et al, 2016; Abdul Wahab et al, 2020). RH has also been used in the synthesis of MCM-22 zeolite for adsorption and catalysis (Cheng et al, 2012), silicate- phosphate glasses (Kaur et al, 2020), and biosilicate ceramics (Choudhary et al, 2021).

Concrete

Due to greater attention to environmental preservation and economic sustainability, recycled aggregate concrete (RAC), which consists of aggregates from recycling clean concrete waste with little other building waste (Marinkovi? and Carevi?, 2019), has started to be used in place of natural aggregate concrete (NAC), which is made from natural aggregates extracted from nature (Ali Qureshi et al, 2020; Yuan et al, 2021).However, RAC is less durable compared with NAC because of being highly porous (Ali Qureshi et al, 2020). The durability of RAC can be increased by additives of different kinds, including RHA (Ali Qureshi et al, 2020; Hu et al, 2020). The use of RHA in on-shore structures helps cement improve its durability, avoid cracks, and enhance its anti-fouling properties, making it a green self-consolidating concrete (Lertwattanaruk and Makul, 2021). A mixture of RHA (5%), sugarcane bagasse ash (5%), and cement (90%) has been shown to produce better concretes (Channa et al, 2022).

Fig. 5. Steps in ceramic production from rich husk (RH).

RHA can be used as sodium silicate in alkali- activated slag to assist in cementing and the production of a Portland cement type with greater mechanical strength (Ataie, 2021; Shaaban, 2021). A combination of RHA (15.00%), polypropylene (0.25%), and cement (84.75%) results in reinforced concrete (Memon et al, 2021). RH can be used as a slurry additive due to having large amounts of silica nanoparticles on its surface, making it suitable for the production of cement grouts with greater hydration potential and workability (Carmona et al, 2013; Berktas et al, 2021). RHA increases induction period and hinders hydration heat elevation with no effect on slurry thermal conductivity (Berktas et al, 2021). The application of RHA nanoparticles (3%) (nano-RHA ash) in cement demonstrates its potential in forming ultra-high- performance concrete with the highest compressive strength compared with concrete made from chemical nano-silica (Mostafa et al, 2020).

In recent years, RHA has been extensively used as a supplementary cementitious material in cement-based products as it significantly enhances the strength and durability properties of the resulting cement (Ali Farid and Zaheer, 2023). For instance, the mechanical and microstructural properties of self-compacting concrete are enhanced by partially replacing cement with marble powder and sand with RHA (Chaudhary et al, 2023). Lightweight concrete is another disruptive approach suitable for high-rise buildings, offshore structures, and long-span bridges that benefit from agro-industrial wastes, including RH and its derivatives (Chaudhary et al, 2023). In another successful attempt by Kim et al (2014), RHA was used in place of ordinary Portland cement concrete and demonstrated its high potential in concrete geopolymer development.

Application of RH in soil stabilization and geotechnical engineering

Soil with an organic layer that is being excessively compressed has lower shear strength and therefore requires correction with stabilizing agents (Brahmachary et al, 2019). However, the use of soil stabilizing agents such as cement and lime is at a high cost. Roy (2014) proposed that the use of RHA (10% RHA and 6% cement) could be a suitable low-cost alternative. Evaluation of the addition of RHA to soil has shown that RHA can effectively improve soil performance in response to shrinkage cracking, elevating compressive and shear strength, as well as the California bearing ratio value, which indicates economic and environmental benefits (Chen et al, 2021). In a recent study, RHA and pozzolan cement were used as soil stabilization materials, significantly improving soil stability (Wibowo et al, 2023).

Another high-cost operation in civil activities is pavement construction, especially in areas where expansive clay represents the majority of the alignment soil. In an attempt to mitigate this, a new combination of 20% by weight RHA and about 2% by weight natural lime improves the California bearing ratio of expansive clay soil by 800% (Karatai et al, 2017). Subsequently, soil plasticity was reduced by about 90%,and free swell decreased by nearly 70%, demonstrating RHA’s potential as a cost-effective green technology that provides the necessary strength to clay soils (Karatai et al, 2017).

Geotechnical engineers often use fly ash or pozzolanic materials to improve the engineering properties of clay soils. Based on the assessment of pozzolanic activity, RHA has proven to be promising for soil improvement and civil engineering. For example, mixing RHA with clay increases the soil’s mechanical properties (Muntohar and Hantoro, 2000).

Brick industry

Bricks are basic building materials that account for 15% of the circumventing cost. The use of agricultural wastes such as bagasse ash and RH in brick production, alongside traditional cement, has significantly reduced costs. Additionally, the resulting bricks are more resistant and lighter than traditional clay bricks (Kumaret al, 2022). Insulating firebricks, made from porous kaolin, possessing low thermal conductivity and high temperature resistance, are created by mixing organic matter with clay and then burning to form pores (Ugheoke et al, 2006). RH is a suitable combustible material with the potential to produce porous insulating firebricks (Isinkaye et al, 2015; Ewais et al, 2017; Hossain et al, 2021). RHA is also used to produce construction products such as cement and bricks (Jittin et al, 2020). Research has shown that a mixture of kaolin, rice clay, and plastic clay (in a ratio of 4:1:2) provides good insulation and a refractory surface with optimal performance (Ugheoke et al, 2006).

Pharmacy and medicine

Drugs are formulated with the help of additives in appropriate doses (Ugwu et al, 2019). The availability of excipients, used as disintegrants, binders, gelling agents, lubricants, flavorings, emulsifiers, suspending agents, bulking agents, and sweeteners, saves on pharmaceutical costs and facilitates ease of use in drug production (Ogaji et al, 2012). Biopolymers such as cellulose serve as excipients, and cellulose derived from RH can be used for this purpose (Uwaezuoke et al, 2014; Ugwu et al, 2019). Aerosil 200V, a well-known additive in various drug formulations, can be effectively replaced by silica obtained from RH (Fernández_ Ledesma et al, 2015; Carmen et al, 2017). In addition to use in formulating tablets, silica from RH is also used to thicken gels and manufacture photovoltaic cells and thixotropic agents (Rowe et al, 2009). Furthermore, RH contains xylooligosaccharides, which act as a prebiotic to promote the growth and activity of intestinal microbiota, with proven ameliorative effects on various diseases, including insulin resistance and diabetes (Khat-udomkiri et al, 2020). RH also contains phenolics and flavonoids that promote health and well-being (Lourith and Kanlayavattanakul, 2013). Additionally, RH can assist obese individuals in reducing their appetites (Edrisi et al, 2018).RH liquid smoke can ameliorate periodontitis by reducing inflammation (Budhy et al, 2021). RHA can be used to synthesize zeolite (aluminosilicate), which has been shown to have lung anticancer properties (Jesudoss et al, 2018). In a diabetic rat model, RH is used as a prebiotic to control blood sugar levels via preserving the intestinal microbiome (Khat-udomkiri et al, 2020).

The preventive effect of purple RH extract on enzyme induction activity in murine hepatoma cells has been reported, demonstrating potent cancer chemopreventive activity in rat liver micronucleus tests, possibly due to vitamin E and phenolic compounds (Chariyakornkul et al, 2019).

RHA also has applications in producing bioactive glass for use as bone regeneration materials (Wu et al, 2009) and scaffolds in implant materials (Kaur et al, 2020). Similarly, silica-metal phosphate nanocomposites made using RH show excellent biocompatibility with human mesenchymal stem cells and can be used in bone tissue engineering (Athinarayanan et al, 2014).Homogeneous silica nanoparticles from RH have been used in biosensors, bioimaging, drug delivery, and the manufacturing of SARS-CoV-2 anti-masks (Prabha et al, 2021).

Recently, agricultural waste such as RHA has been used as a biomaterial in biocompatible products. For example, RHA can be used to produce wollastonite, employed for bone repair, implants, and tissue regeneration (Ismail and Mohamad, 2021). RH, an inexpensive source of amorphous silica for the production of silicon-based materials, is an environmentally friendly and low-cost waste source for commercial silica precursors (Bahrami et al, 2015b, 2017; Soltani et al, 2017). RH-based biogenic silica-metal phosphate nano- composites can be used in bone tissue engineering (Athinarayanan et al, 2014). RH flour has been used to produce poly (3-hydroxy-butyrate) composite with applications in food packaging (Melendez-Rodriguez et al, 2019).

Nanobiotechnology

The industrial conversion of quartz sand and sodium carbonate to produce silica is an energy-dependent process (Affandi et al, 2009). RH is utilized to produce pure silica (Azat et al, 2019), and RHA can be used to generate nano-silica, which has applications as fillers (Motaung and Luyt, 2010), in pharmaceuticals (Morpurgo et al, 2010), as catalysts (Pode, 2016), and in chromatography (Bakaev and Pantano, 2009) through thermal and chemical methods. Heating RHA at temperatures between 500 oC and 700 oC leads to the production of amorphous nano-silica, while temperatures above 900 oC facilitate the formation of the crystal structures of nano-silica (Chandrasekhar et al, 2006).

RHA nano-silica serves as an effective and biocompatible carrier for drug delivery, including the delayed release of antibiotics (Salavati-Niasari et al, 2013) and anticancer drugs like doxorubicin (Porrang et al, 2021). RH also acts as a reducing agent in the green synthesis of silver nanoparticles with antibacterial activities (Suwan et al, 2018; Zhang et al, 2021). RH nano-silica functionalized with 5-fluorouracil using chitosan as an intermediate was tested on cancer cell lines and fibroblast cell lines, demonstrating significant toxicity to the former and minimal toxicity to the latter (Dhinasekaran et al, 2020).

Nanostructured mesoporous materials synthesized from RH and surface-modified with Fe were evaluated as photocatalytic degradation agents for the removal of various endocrine-disrupting chemicals, such as herbicides (atrazine), and compounds sourced from the plastic (bisphenol A) and pharmaceutical industries (acetaminophen) (Carraro et al, 2021). RH nano-silica surface-modified with poly diallyl dimethyl ammonium chloride polyelectrolyte exhibits adsorption potential, as evidenced by the removal of antibiotics from an aqueous solution (Pham et al, 2018). RH nanozeolite has shown potential for wastewater cleansing by removing paint from contaminated water (Oviedo et al, 2022). Surface-modified nano-silica with protein has been an efficient adsorbent for removing antibiotics such as ciprofloxacin in an environmentally friendly manner (Pham et al, 2020).

Economic impact

The significance and various applications of RH across different fields make it economically important in numerous areas.Therefore, discovering sustainable solutions for using RH in rice-producing countries is crucial. For example, RHA, with a wide range of applications in various forms, reduces greenhouse gases by up to 1005 kg/t of product, lowers costs by up to 8000 THB/t of product, and generates employmentequivalent to 5 person-years per million THB (Prasara-A and Gheewala, 2017).RHA enables the replacementof conventional products, offering substantial economic benefits that are difficult to compare with any other bioconversions (Balo, 2015). For instance, in Nigeria, RH is used for electricity generation to produce clean and affordable energy, proving to be economically viable with a net present value of $1.68 million and a levelized cost of electricity between $0.07?0.11/kWh (Salisu et al, 2021). In a comparable study in Thailand, where rice is a staple food and RH is used as an alternative energy source, over 6 million tons of RH (amounting to 70% of the total RH produced) are combusted annually to power numerous in-built power plants (Prasara-A and Gheewala, 2017).

Concluding remarks and prospects

The direct use of RH or its derivatives can reduce the cost of agricultural waste disposal, while producing valuable compounds or even materials for components or devices such as solar cells and Li-ion batteries. Numerous applications have been reported for RH derivatives, namely, RHA, RHB, RHH, and RHAC. Current studies demonstrate a wide range of RH applications across various fields, including the agricultural industry, environmental sector, construction industry, fuel industry, modern energy sector, pharmaceutical industry, medicine, nanotechnology, and biotechnology. For example, RH is used directly in remediation and has many applications in medicine due to its high silica content. Recently, silica nanoparticles derived from RH have proven to be very effective in producing protection masks against COVID-19. Today, RH serves as a crucial raw material in the bioeconomy by supporting the agricultural industry. Its efficient use can help increase farm productivity and rural development. The rapidly growing volume of scientific and technological publications on RH reflects the constant evolution of its use, from high-tonnage traditional applications to more specialized and advanced small-amount uses, with broader prospects anticipated in other fields in the forthcoming years. These latter applications include the semiconductor and nanotechnology industries, two of the most influential drivers in today’s society. Thus, the economic impact of RH will influence not only rice-producing countries but also those where it will be consumed as a value-added product. This review presents a comprehensive overview of its applications for the first time. In the future, high-throughput methodologies need to be implemented to rapidly screen genotypes for targeted applications, an aspect that has mostly been neglected.

Future perspective

So far, the genes coding for RH compounds have not been identified or studied through genome-wide association study, QTL mapping, etc. By using the rice collection obtained from the International Rice Research Institute and analyzing the shell compositions of different rice genotypes as well as other shell characteristics, we can identify the genes encoding these traits. In the future, we can understand the genotypic characteristics by exploring the great diversity that exists among the husks of this rice collection.

Abazari A, Navidshad B, Aghjehgheshlagh F M, Nikbin S. 2016. The effect of rice husk as an insoluble dietary fiber source on intestinal morphology andandpopulations in broilers., 10: 217?224.

Abdul Wahab R A, Mohd Zaid M H, Aziz S H A, Amin Matori K, Fen Y W, Yaakob Y. 2020. Effects of sintering temperature variation on synthesis of glass-ceramic phosphor using rice husk ash as silica source., 13(23): 5413.

Abigail M E A, Samuel S M, Chidambaram R. 2016. Application of rice husk nanosorbents containing 2,4-dichlorophenoxyacetic acid herbicide to control weeds and reduce leaching from soil., 63: 318–326.

Adeniji A A, Oluwafemi R A, Akinpelu O B. 2014. The feeding value of rice husk with or without probiotics and enzyme supplementation in replacing groundnut cake in the diets of juvenile snails ()., 4(9): 15?27.

Adnan M, Asif M, Khalid M, Abbas B, Hayyat M S, Raza A, Khan B A, Hassan M, Khan M A B, Hanif M S. 2020. Role of mulches in agriculture: A review., 3: 309?314.

Affandi S, Setyawan H, Winardi S, Purwanto A, Balgis R. 2009. A facile method for production of high-purity silica xerogels from bagasse ash., 20(5): 468–472.

Afjeh M S, Marandi G B, Zohuriaan-Mehr M J. 2020. Nitrate removal from aqueous solutions by adsorption onto hydrogel-rice husk biochar composite., 92(6): 934–947.

Ahmadabadi Z, Zarei M, Yasrebi J, Ronaghi A, Ghasemi R, Sadegh Kasmaei L, Bloem E, Schnug E. 2019. How can organic amendments help to bind sulfadiazine in the soil? An Iranian soil study., 50(19): 2397–2410.

Akinyemi B A, Kolajo T E, Adedolu O. 2022. Blended formaldehyde adhesive bonded particleboards made from groundnut shell and rice husk wastes., 24(6): 1653–1662.

Ali Farid S, Zaheer M M. 2023. Production of new generation and sustainable concrete using rice husk ash (RHA): A review..(in press)

Ali M S, Azmah Hanim M A, Tahir S M, Jaafar C N A, Mazlan N, Amin Matori K. 2017. The effect of commercial rice husk ash additives on the porosity, mechanical properties, and microstructure of alumina ceramics., 2017: 1–10.

Ali Qureshi L, Ali B, Ali A. 2020. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete., 263: 120636.

Amiri M J, Bahrami M, Beigzadeh B, Gil A. 2018. A response surface methodology for optimization of 2,4-dichlorophenoxyacetic acid removal from synthetic and drainage water: A comparative study., 25(34): 34277–34293.

Ansari S, Mousavi A, Safarnejad M R, Farrokhi N, Alavi S M, Schillberg S, N?lke G. 2021. Selection and characterization of two monoclonal antibodies specific for themajor antigenic cell wall protein Aflmp1., 125(8): 621–629.

Anyakorah C I, Dike E N. 2013. Comparison of sawdust and rice husk as casing materials forpropagation on cassava peel substrate., 4(5): 552–554.

Aprilia S, Rosnelly C M, Zuhra, Fitriani F, Haffiz Akbar E, Raqib M, Rahmah K, Amin A, Baity R A. 2023. Synthesis of amorphous silica from rice husk ash using the sol-gel method: Effect of alkaline and alkaline concentration.(in press)

Arjmandi R, Hassan A, Majeed K, Zakaria Z. 2015. Rice husk filled polymer composites., 2015: 1–32.

Asadi H, Ghorbani M, Rezaei-Rashti M, Abrishamkesh S, Amirahmadi E, Chen C R, Gorji M. 2021. Application of rice husk biochar for achieving sustainable agriculture and environment., 28(): 325–343.

Ataie F F. 2021. Utilization of treated agricultural residue ash as sodium silicate in alkali activated slag systems., 14(2): 329.

Athinarayanan J, Periasamy V S, Alshatwi A A. 2014. Biogenic silica-metal phosphate (metal = Ca, Fe or Zn) nanocomposites: Fabrication from rice husk and their biomedical applications.:, 25(7): 1637–1644.

Azat S, Korobeinyk A V, Moustakas K, Inglezakis V J. 2019. Sustainable production of pure silica from rice husk waste in Kazakhstan., 217: 352–359.

Badar R, Qureshi S A. 2014. Composted rice husk improves the growth and biochemical parameters of sunflower plants., 2014: 1–6.

Bahrami A, Pech-Canul M I, Gutiérrez C A, Soltani N. 2015a. Effect of rice-husk ash on properties of laminated and functionally graded Al/SiC composites by one-step pressureless infiltration., 644: 256–266.

Bahrami A, Pech-Canul M I, Gutiérrez C A, Soltani N. 2015b. Wetting and reaction characteristics of crystalline and amorphous SiO2derived rice-husk ash and SiO2/SiC substrates with Al-Si-Mg alloys., 357: 1104–1113.

Bahrami A, Simon U, Soltani N, Zavareh S, Schmidt J, Pech-Canul M I, Gurlo A. 2017. Eco-fabrication of hierarchical porous silica monoliths by ice-templating of rice husk ash., 19(1): 188–195.

Bakaev V A, Pantano C G. 2009. Inverse reaction chromatography: 2. Hydrogen/deuterium exchange with silanol groups on the surface of fumed silica., 113(31): 13894–13898.

Balarak D, Mostafapour F K, Azarpira H. 2016. Adsorption isotherm studies of tetracycline antibiotics from aqueous solutions by maize stalks as a cheap biosorbent., 8: 16664–16675.

Balarak D, Mostafapour F K. 2019. Photocatalytic degradation of amoxicillin using UV/synthesized NiO from pharmaceutical wastewater., 19(1): 211–218.

Balarak D, Bandani F, Shehu Z, Ahmed N J. 2020. Adsorption properties of thermally treated rice husk for removal of sulfamethazine antibiotic from pharmaceutical wastewater., 32: 84–92.

Balo F. 2015. Feasibility study of ‘green’ insulation materials including tall oil: Environmental, economical and thermal properties., 86: 161–175.

Basu P. 2018. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory. 3rd edn. San Diego, CA, USA:Academic Press.

Batagarawa S M, Ajibola A K. 2019. Comparative evaluation for the adsorption of toxic heavy metals on to millet, corn and rice husks as adsorbents., 8(3): 119–125.

Berktas I, Chaudhari O, Ghafar A N, Menceloglu Y, Okan B S. 2021. Silanization of SiO2decorated carbon nanosheets from rice husk ash and its effect on workability and hydration of cement grouts., 11(3): 655.

Bernardo M M S, Madeira C A C, dos Santos Nunes N C L, Dias D A C M, Godinho D M B, de Jesus Pinto M F, do Nascimento Matos I A M, Carvalho A P B, de Figueiredo Ligeiro Fonseca I M. 2017. Study of the removal mechanism of aquatic emergent pollutants by new bio-based chars., 24(28): 22698–22708.

Betiha M A, Moustafa Y M, El-Shahat M F, Rafik E. 2020. Polyvinylpyrrolidone-Aminopropyl-SBA-15 schiff Base hybrid for efficient removal of divalent heavy metal cations from wastewater., 397: 122675.

Bhullar N K, Gruissem W. 2013. Nutritional enhancement of rice for human health: The contribution of biotechnology., 31(1): 50–57.

Bisht N, Gope P C, Rani N. 2020. Rice husk as a fibre in composites: A review., 29(1): 147–162.

Biswas B, Pandey N, Bisht Y, Singh R, Kumar J, Bhaskar T. 2017. Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk., 237: 57–63.

Bodie A R, Micciche A C, Atungulu G G, Rothrock M J, Ricke S C. 2019. Current trends of rice milling byproducts for agricultural applications and alternative food production systems., 3: 47.

Brahmachary T K, Ahsan M K, Rokonuzzaman M. 2019. Impact of rice husk ash (RHA) and nylon fiber on the bearing capacity of organic soil., 1(3): 1–13.

Budhy T I, Arundina I, Surboyo M D C, Halimah A N. 2021. The effects of rice husk liquid smoke in: Induced periodontitis., 15: 653–659.

Bushra B, Remya N. 2020. Biochar from pyrolysis of rice husk biomass: Characteristics, modification and environmental application., 2020: 1–12.

Cai J, Zhang D, Ding W P, Zhu Z Z, Wang G Z, He J R, Wang H B, Fei P, Si T L. 2020. Promising rice-husk-derived carbon/Ni(OH)2composite materials as a high-performing supercapacitor electrode., 5(46): 29896–29902.

Campos P, Knicker H, Miller A Z, Velasco-Molina M, De la Rosa J M. 2021. Biochar ageing in polluted soils and trace elements immobilisation in a 2-year field experiment., 290: 118025.

Carmen SH, Mercedes SH, Rocio L R, Enrique E R, Agustin Hilario R R. 2017. Silica from rice as new drug delivery systems.: Amanullah, Fahad S. Rice: Technology and Production. Croatia: InTech: 69.

Carmona V B, Oliveira R M, Silva W T L, Mattoso L H C, Marconcini J M. 2013. Nanosilica from rice husk: Extraction and characterization., 43: 291–296.

Carraro P M, Benzaquén T B, Eimer G A. 2021. Eco-friendly synthesis of nanostructured mesoporous materials from natural source rice husk silica for environmental applications., 28(19): 23707–23719.

Carter C B, Norton M G. 2007. Ceramic Materials: Science and Engineering. Amsterdam, the Netherlands: Springer.

Chaitanoo N, Aggarangsi P, Nitayavardhana S. 2021. Improvement of solid-state anaerobic digestion of broiler farm-derived waste via fungal pretreatment., 332: 125146.

Chaiwong N, Pusadee T, Jamjod S, Prom-U-Thai C. 2022. Silicon application promotes productivity, silicon accumulation and upregulates silicon transporter gene expression in rice., 11(7): 989.

Chalapud M C, Herdt M, Nicolao E S, Ruseckaite R A, Ciannamea E M, Stefani P M. 2020. Biobased particleboards based on rice husk and soy proteins: Effect of the impregnation with tung oil on the physical and mechanical behavior., 230: 116996.

Chandrasekhar S, Pramada P N, Majeed J. 2006. Effect of calcination temperature and heating rate on the optical properties and reactivity of rice husk ash., 41(23): 7926–7933.

Channa S H, Ali Mangi S, Bheel N, Soomro F A, Khahro S H. 2022. Short-term analysis on the combined use of sugarcane bagasse ash and rice husk ash as supplementary cementitious material in concrete production., 29(3): 3555–3564.

Chariyakornkul A, Punvittayagul C, Taya S, Wongpoomchai R. 2019. Inhibitory effect of purple rice husk extract on AFB1-induced micronucleus formation in rat liver through modulation of xenobiotic metabolizing enzymes., 19(1): 1–11.

Chatveera B, Lertwattanaruk P. 2014. Evaluation of nitric and acetic acid resistance of cement mortars containing high-volume black rice husk ash., 133: 365–373.

Chaudhary N, Mohanty I, Saha P, Kumari R, Kumar Pandey A. 2023. Performance of resource saving agro-industrial wastes and their utilization in lightweight concrete: A review..(in press)

Cheenmatchaya A, Kungwankunakorn S. 2014. Preparation of activated carbon derived from rice husk by simple carbonization and chemical activation for using as gasoline adsorbent., 5: 171–175.

Chen R F, Congress S S C, Cai G J, Duan W, Liu S Y. 2021. Sustainable utilization of biomass waste-rice husk ash as a new solidified material of soil in geotechnical engineering: A review., 292: 123219.

Chen R S, Ahmad S, Gan S, Tarawneh M A. 2020. High loading rice husk green composites: Dimensional stability, tensile behavior and prediction, and combustion properties., 33(7): 882–897.

Chen Y E, Zhu Y C, Wang Z C, Li Y, Wang L L, Ding L L, Gao X Y, Ma Y J, Guo Y P. 2011. Application studies of activated carbon derived from rice husks produced by chemical-thermal process: A review., 163(1): 39–52.

Cheng Y E, Lu M, Li J S, Su X Y, Pan S L, Jiao C A, Feng M H. 2012. Synthesis of MCM-22 zeolite using rice husk as a silica source under varying-temperature conditions., 369(1): 388–394.

Chien C C, Huang Y P, Sah J G, Cheng W J, Chang R Y, Lu Y S. 2011. Application of rice husk charcoal on remediation of acid soil., 685: 169–180.

Cho W C, Kim H J, Lee H I, Seo M W, Ra H W, Yoon S J, Mun T Y, Kim Y K, Kim J H, Kim B H, Kook J W, Yoo C Y, Lee J G, Choi J W. 2016.5L-scale magnesio-milling reduction of nanostructured SiO2for high capacity silicon anodes in lithium-ion batteries., 16(11): 7261–7269.

Chockalingam E, Subramanian S. 2006. Studies on removal of metal ions and sulphate reduction using rice husk andwith reference to remediation of acid mine drainage., 62(5): 699–708.

Choudhary R, Venkatraman S K, Bulygina I, Senatov F, Kaloshkin S, Anisimova N, Kiselevskiy M, Knyazeva M, Kukui D, Walther F, Swamiappan S. 2021. Biomineralization, dissolution and cellular studies of silicate bioceramics prepared from eggshell and rice husk., 118: 111456.

Chowdhury S, Mishra R, Saha P, Kushwaha P. 2011. Adsorption thermodynamics, kinetics and isosteric heat of adsorption of malachite green onto chemically modified rice husk.,265: 159–168.

Chungsangunsit T, Gheewala S H, Patumsawad S. 2005. Environmental assessment of electricity production from rice husk: A case study in Thailand., 6(1): 47–55.

Cope C O, Webster D S, Sabatini D A. 2014. Arsenate adsorption onto iron oxide amended rice husk char., 488/489: 554–561.

Crini G. 2006. Non-conventional low-cost adsorbents for dye removal: A review., 97(9): 1061–1085.

Cui J H, Yang Y H, Hu Y H, Li F B. 2015. Rice husk based porous carbon loaded with silver nanoparticles by a simple and cost-effective approach and their antibacterial activity., 455: 117–124.

Danewalia S S, Sharma G, Thakur S, Singh K. 2016. Agricultural wastes as a resource of raw materials for developing low-dielectric glass-ceramics., 6: 24617.

Darabi S F S, Bahramifar N, Ali Khalilzadeh M. 2018. Equilibrium, thermodynamic and kinetics studies on adsorption of eosin Y and red X-GRL from aqueous solution by treated rice husk., 5(1): 392–398.

Debona D, Rodrigues F A, Datnoff L E. 2017. Silicon’s role in abiotic and biotic plant stresses., 55: 85–107.

Deokar S K, Mandavgane S A, Kulkarni B D. 2016. Agro-industrial waste: A low cost adsorbent for effective removal of 4-chloro-2-methylphenoxyacetic acid herbicide in batch and packed bed modes., 23(16): 16164–16175.

Derakhshan-Nejad Z, Jung M C. 2019. Remediation of multi-metal contaminated soil using biochars from rice husk and maple leaves., 21(3): 457–468.

Dey S, Haripavan N, Basha S R, Babu G V. 2021. Removal of ammonia and nitrates from contaminated water by using solid waste bio-adsorbents., 1: 100005.

Dhankhar P. 2014. Rice milling., 4(5): 34–42.

Dhinasekaran D, Raj R, Rajendran A R, Purushothaman B, Subramanian B, Prakasarao A, Singaravelu G. 2020. Chitosan mediated 5-fluorouracil functionalized silica nanoparticle from rice husk for anticancer activity., 156: 969–980.

Duan Y M, Yang J F, Song Y F, Chen F N, Li X F, Awasthi M K, Li H K, Zhang L S. 2021. Clean technology for biochar and organic waste recycling, and utilization in apple orchard., 274: 129914.

Ebe S, Ohike T, Matsukawa T, Okanami M, Kajiyama S, Ano T. 2019. Promotion of lipopeptide antibiotic production bysp. IA in the presence of rice husk biochar., 44(1): 33–40.

Edrisi F, Salehi M, Ahmadi A, Fararoei M, Rusta F, Mahmoodianfard S. 2018. Effects of supplementation with rice husk powder and rice bran on inflammatory factors in overweight and obese adults following an energy-restricted diet: A randomized controlled trial., 57(2): 833–843.

El-Sanhoury M. 2018. Efficiency of using rice husks in feeding growing rabbits as anti-aflatoxins., 21(1): 103–112.

Ewais E M M, Elsaadany R M, Ahmed A A, Shalaby N H, Al-Anadouli B E H. 2017. Insulating refractory bricks from water treatment sludge and rice husk ash., 58(2): 136–144.

Fernández_Ledesma E, Rodríguez_Acosta C, Liva_Garrido M, Díaz_Polanco I, Cazanave_Guarnaluce D. 2015. Evaluation of rice husk as an excipient for the pharmaceutical industry., 6(1): 114–118.

Firdus F, Samadi S, Muhammadar A A, Sarong M A, Muchlisin Z A, Sari W, Batubara A S. 2020. Gut and intestinal biometrics of the giant trevally,, fed an experimental diet with difference sources of activated charcoal., 9: 444.

Frimpong-Manso J, Obodai M, Dzomeku M, Apertorgbor M M. 2011. Influence of rice husk on biological efficiency and nutrient content of(Jacq. ex. Fr.) Kummer., 18(1): 249–254.

Fu J R, Zhu L X, Sun X T, Zhou D H, Ouyang L J, Bian J M, He H H, Xu J. 2015. Genetic analysis of grain shape and weight after cutting rice husk., 14(4): 17739–17748.

Gao Y, Guo X B, Liu Y, Fang Z Q, Zhang M W, Zhang R F, You L J, Li T, Liu R H. 2018. A full utilization of rice husk to evaluate phytochemical bioactivities and prepare cellulose nanocrystals., 8: 10482.

Garba J, Samsuri W A, Othman R, Ahmad Hamdani M S. 2019. Evaluation of adsorptive characteristics of cow dung and rice husk ash for removal of aqueous glyphosate and aminomethyl- phoshonic acid., 9: 17689.

Ge X M, Xu F Q, Li Y B. 2016. Solid-state anaerobic digestion of lignocellulosic biomass: Recent progress and perspectives., 205: 239–249.

Gopal P M, Sivaram N M, Barik D. 2019. Paper industry wastes and energy generation from wastes.: Barik D. Energy from Toxic Organic Waste for Heat and Power Generation. Amsterdam, the Netherlands: Elsevier:83–97.

Gursel I V, Elbersen B, Meesters K P H, van Leeuwen M. 2022. Defining circular economy principles for biobased products., 14(19): 12780.

Hemnath A, Anbuchezhiyan G, NanthaKumar P, Senthilkumar N. 2021. Tensile and flexural behaviour of rice husk and sugarcane bagasse reinforced polyester composites., 46: 3451–3454.

Hoerudin, Setyawan N, Suismono, Purwaningsih H, Apriliani N. 2022. Morphology, extraction yield, and properties of biogenic silica nanoparticles from Indonesian rice husk as influenced by solvent type and aging time.:, 1024(1): 012076.

Hossain S S, Roy P K. 2019. Fabrication of sustainable insulation refractory: Utilization of different wastes., 58(3): 115–125.

Hossain S S, Bae C J, Roy P K. 2021. A replacement of traditional insulation refractory brick by a waste-derived lightweight refractory castable., 18(5): 1783–1791.

Hu L L, He Z, Zhang S P. 2020. Sustainable use of rice husk ash in cement-based materials: Environmental evaluation and performance improvement., 264: 121744.

Humphreys E, Gaydon D S, Eberbach P L. 2016. Evaluation of the effects of mulch on optimum sowing date and irrigation management of zero till wheat in central Punjab, India using APSIM., 197: 83–96.

Isinkaye EO, Shado AS, Sanya OT. 2015. Development and characterization of rice husk insulating bricks from two selected deposits in Ekiti State, Nigeria., 6: 132–138.

Ismail H, Mohamad H. 2021. Bioactivity and biocompatibility properties of sustainable wollastonite bioceramics from rice husk ash/rice straw ash: A review., 14(18): 5193.

Jesudoss S K, Judith Vijaya J, Kaviyarasu K, Iyyappa Rajan P, Narayanan S, John Kennedy L. 2018.anti-cancer activity of organic template-free hierarchical M (Cu, Ni)-modified ZSM-5 zeolites synthesized using silica source waste material., 186: 178–188.

Jing X, Wang T F, Yang J L, Wang Y L, Xu H F. 2018. Effects of biochar on the fate and toxicity of herbicide fenoxaprop-ethyl in soil., 5(5): 171875.

Jittin V, Bahurudeen A, Ajinkya S D. 2020. Utilisation of rice husk ash for cleaner production of different construction products., 263: 121578.

Kadam A A, Telke A A, Lade H S, Saratale R G, Saratale G D. 2023. Agro-industrial waste biomass utilization via solid-state fermentation for textile wastewater treatment.: Larroche C, Sanroman M A, Du G C, Pandey A. Current Developments in Bioengineering and Biotechnology. Amsterdam, the Netherlands: Elsevier: 253–277.

Kalderis D, Bethanis S, Paraskeva P, Diamadopoulos E. 2008. Production of activated carbon from bagasse and rice husk by a single-stage chemical activation method at low retention times., 99(15): 6809–6816.

Kalderis D, Kotti M S, Méndez A, Gascó G. 2014. Characterization of hydrochars produced by hydrothermal carbonization of rice husk., 5(1): 477–483.

Kandanelli R, Meesala L, Kumar J, Raju C S K, Rao Peddy V C, Gandham S, Kumar P. 2018. Cost effective and practically viable oil spillage mitigation: Comprehensive study with biochar., 128: 32–40.

Kaniapan S, Pasupuleti J, Patma Nesan K, Abubackar H N, Umar H A, Oladosu T L, Bello S R, Rene E R. 2022. A review of the sustainable utilization of rice residues for bioenergy conversion using different valorization techniques, their challenges, and techno-economic assessment., 19(6): 3427.

Karatai T R, Kaluli J W, Kabubo C, Thiong’o G. 2017. Soil stabilization using rice husk ash and natural lime as an alternative to cutting and filling in road construction., 143(5): 04016127.

Kaur D, Reddy M S, Pandey O P. 2020.bioactivity of silicate-phosphate glasses using agriculture biomass silica.:, 31(8): 65.

Kaur R, Singh H. 2017. Bio-ethanol production from rice-husk usingsimultaneous saccharification and fermentation and optimization of pre-treatment methods., 9(7): 1–7.

Khat-udomkiri N, Toejing P, Sirilun S, Chaiyasut C, Lailerd N. 2020. Antihyperglycemic effect of rice husk derived xylooligo- saccharides in high-fat diet and low-dose streptozotocin-induced type 2 diabetic rat model., 8(1): 428–444.

Kim Y Y, Lee B J, Saraswathy V, Kwon S J. 2014. Strength and durability performance of alkali-activated rice husk ash geopolymer mortar., 2014: 1–10.

Kiran B R, Prasad M N V. 2019. Biochar and rice husk ash assisted phytoremediation potentials ofL. for lead-spiked soils., 183: 109574.

Kolar P, Jin H. 2019. Baseline characterization data for raw rice husk., 25: 104219.

Koskin A P, Zibareva I V, Vedyagin A A. 2020. Conversion of rice husk and nutshells into gaseous, liquid, and solid biofuels.: Nanda S, Vo D V N, Sarangi K. Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals. Singapore: Springer: 171–194.

Kumar D C, Vasanthi P, Devaraju A. 2022. Development of agro-industrial wastes in material production.: Palani IA, Sathiya P, Palanisamy D. Recent Advances in Materials and Modern Manufacturing. Singapore: Springer: 973–981.

Kumar S, Sangwan P, Dhankhar R M V, Bidra S. 2013. Utilization of rice husk and their ash: A review., 1: 126–129.

Lacey L A, Grzywacz D, Shapiro-Ilan D I, Frutos R, Brownbridge M, Goettel M S. 2015. Insect pathogens as biological control agents: Back to the future., 132: 1–41.

Laidlaw M A S, Filippelli G M, Brown S, Paz-Ferreiro J, Reichman S M, Netherway P, Truskewycz A, Ball A S, Mielke H W. 2017. Case studies and evidence-based approaches to addressing urban soil lead contamination., 83: 14–30.

Lalruatsangi E, Hazarika BN, Raja P. 2018. Effect of paddy straw and rice husk mulching on soil microbial population in acid lime (Swingle)., 77: 241–243.

Lertwattanaruk P, Makul N. 2021. Influence of ground calcium carbonate waste on the properties of green self-consolidating concrete prepared by low-quality bagasse ash and rice husk ash., 14(15): 4232.

Li X X, Wang X L, Chen Y D, Yang X Y, Cui Z J. 2019. Optimization of combined phytoremediation for heavy metal contaminated mine tailings by a field-scale orthogonal experiment., 168: 1–8.

Li Y, Hagos F M, Chen R R, Qian H X, Mo C X, Di J, Gai X K, Yang R Q, Pan G X, Shan S D. 2021. Rice husk hydrochars from metal chloride-assisted hydrothermal carbonization as biosorbents of organics from aqueous solution., 8(1): 1–15.

Li Y N, Wang R, Chen Z X, Zhao X P, Luo X H, Wang L, Li Y F, Teng F. 2020. Preparation of magnetic mesoporous silica from rice husk for aflatoxin B1 removal: Optimum process and adsorption mechanism., 15(9): e0238837.

Li Z M, Song Z L, Cornelis J T. 2014. Impact of rice cultivar and organ on elemental composition of phytoliths and the release of bio-available silicon., 5: 529.

Liang Y C, Nikolic M, Bélanger R, Gong H J, Song A L.2015.Silicon-mediated tolerance to metal toxicity.: Liang Y C, Nikolic M, Bélanger R, Gong H J, Song A L. Silicon in Agriculture: From Theory to Practice. Dordrecht, the Netherlands: Springer: 83–122.

Liu X Y, Yang L, Zhao H T, Wang W. 2020. Pyrolytic production of zerovalent iron nanoparticles supported on rice husk-derived biochar: Simple,synthesis and use for remediation of Cr(VI)-polluted soils., 708: 134479.

Lourith N, Kanlayavattanakul M. 2013. Appraisal of Thai glutinous rice husk for health promotion products., 57(3): 343–347.

Mahmad-Toher A S, Govender N, Dorairaj D, Wong M Y. 2022. Comparative evaluation on calcium silicate and rice husk ash amendment for silicon-based fertilization of Malaysian rice (L.) varieties., 45(9): 1336–1347.

Majeed K, Arjmandi R, Al-Maadeed M A, Hassan A, Ali Z, Khan A U, Khurram M S, Inuwa I M, Khanam P N. 2017. Structural properties of rice huskand its polymer matrix composites.: Jawaid M, Tahir P M, Saba N. Lignocellulosic Fibre and Biomass-Based Composite Materials. Amsterdam, the Netherlands: Elsevier: 473–490.

Maki M L, Idrees A, Leung K T, Qin W S. 2012. Newly isolated and characterized bacteria with great application potential for decomposition of lignocellulosic biomass., 22(3): 156–166.

Mandal A, Singh N, Purakayastha T J. 2017. Characterization of pesticide sorption behaviour of slow pyrolysis biochars as low cost adsorbent for atrazine and imidacloprid removal., 577: 376–385.

Manpetch P, Singhapong W, Jaroenworaluck A. 2022. Synthesis and characterization of a novel composite of rice husk-derived graphene oxide with titania microspheres (GO-RH/TiO2) for effective treatment of cationic dye methylene blue in aqueous solutions., 29(42): 63917–63935.

Marinkovi? S, Carevi? V. 2019. Comparative studies of the life cycle analysis between conventional and recycled aggregate concrete.: de Brito J, Agrela F. New Trends in Eco-efficient and Recycled Concrete. Amsterdam, the Netherlands: Elsevier: 257–291.

Melendez-Rodriguez B, Torres-Giner S, Aldureid A, Cabedo L, Lagaron J M. 2019. Reactive melt mixing of poly(3-hydroxybutyrate)/rice husk flour composites with purified biosustainably produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate)., 12(13): 2152.

Memon M J, Jhatial A A, Murtaza A, Raza M S, Phulpoto K B. 2021. Production of eco-friendly concrete incorporating rice husk ash and polypropylene fibres., 28(29): 39168–39184.

Mopoung S, Udeye V, Viruhpintu S, Yimtragool N, Unhong V. 2020. Water treatment for fish aquaculture system by biochar-supplemented planting panel system., 2020: 1–8.

Morpurgo M, Teoli D, Pignatto M, Attrezzi M, Spadaro F, Realdon N. 2010. The effect of Na2CO3, NaF and NH4OH on the stability and release behavior of sol-gel derived silica xerogels embedded with bioactive compounds., 6(6): 2246–2253.

Mostafa S A, Faried A S, Farghali A A, El-Deeb M M, Tawfik T A, Majer S, Abd Elrahman M. 2020. Influence of nanoparticles from waste materials on mechanical properties, durability and microstructure of UHPC., 13(20): 4530.

Motaung T E, Luyt A S. 2010. Effect of maleic anhydride grafting and the presence of oxidized wax on the thermal and mechanical behaviour of LDPE/silica nanocomposites., 527(3): 761–768.

Mujtaba M, Fraceto L F, Fazeli M, Mukherjee S, Savassa S M, de Medeiros G A, Santo Pereira A D S, Mancini S D, Lipponen J, Vilaplana F. 2023. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics., 402: 136815.

Muntohar S A, Hantoro G. 2000. Influence of rice husk ash and lime on engineering properties of a clayey subgrade., 5: 1–13.

Muscat A, de Olde E M, Ripoll-Bosch R, van Zanten H H E, Metze T A P, Termeer C J A M, van Ittersum M K, de Boer I J M. 2021. Principles, drivers and opportunities of a circular bioeconomy., 2(8): 561–566.

Nair R K, Sawant M R. 2006. Effect of the coating of the polymer blend (polyacrylamide/PEG 6000) on the efficiency of rice husk as a pesticide carrier., 27(7): 1021–1025.

Naseer R, Hashmi A S H, Hassan Z U, Rehman H, Naveed S, Masood F, Tayyab M. 2017. Assessment of feeding value of processed rice husk for lohi sheep in growing phase., 49(5): 1725–1729.

Nayak R K, Athira V G, Selvan D, Kumar S S. 2017. Rice husk as an alternate fuel. 2017 IEEE Technological Innovations in ICT for Agriculture and Rural Development (TIAR). April 7?8, 2017.Chennai, India: IEEE: 126–129.

Nguyen T A H, Ngo H H, Guo W S, Zhang J, Liang S, Yue Q Y, Li Q, Nguyen T V. 2013. Applicability of agricultural waste and by-products for adsorptive removal of heavy metals from wastewater., 148: 574–585.

Nighojkar A, Patidar M K, Nighojkar S. 2019. Pectinases: production and applications for fruit juice beverages.: Grumezescu A M, Holban A M. Processing and Sustainability of Beverages. Amsterdam, the Netherlands: Elsevier: 235–273.

Nizamuddin S, Baloch H A, Siddiqui M T H, Mubarak N M, Tunio M M, Bhutto A W, Jatoi A S, Griffin G J, Srinivasan M P. 2018. An overview of microwave hydrothermal carbonization and microwave pyrolysis of biomass., 17(4): 813–837.

Nizamuddin S, Jadhav A, Qureshi S S, Baloch H A, Siddiqui M T H, Mubarak N M, Griffin G, Madapusi S, Tanksale A, Ahamed M I. 2019. Synthesis and characterization of polylactide/rice husk hydrochar composite., 9: 5445.

O’Connor D, Peng T Y, Li G H, Wang S X, Duan L, Mulder J, Cornelissen G, Cheng Z L, Yang S M, Hou D Y. 2018. Sulfur-modified rice husk biochar: A green method for the remediation of mercury contaminated soil., 621: 819–826.

OECD. 2016. OECD Factbook 2015?2016: Economic, Environmental and Social Statistics. [2023-02-15]. https://www.oecd.org/sdd/ oecd-factbook-18147364.htm.

Ogaji I J, Nep E I, Audu-Peter J D. 2012. Advances in natural polymers as pharmaceutical excipients., 3(1): 146.

Ota K, Mitsushima S, Matsuzawa K, Ishihara A. 2014. Assessing the environmental impact of hydrogen energy production.: Basile A, Lulianelli A. Advances in Hydrogen Production, Storage and Distribution. Amsterdam, the Netherlands: Elsevier: 32–42.

Oviedo L R, Muraro P C L, Pavoski G, Espinosa D C R, Ruiz Y P M, Galembeck A, Rhoden C R B, da Silva W L. 2022. Synthesis and characterization of nanozeolite from (agro) industrial waste for application in heterogeneous photocatalysis., 29: 3794–3807.

Pang S S. 2019. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals., 37(4): 589–597.

Pérez-Marín A B, Ballester A, González F, Blázquez M L, Mu?oz J A, Sáez J, Zapata V M. 2008. Study of cadmium, zinc and lead biosorption by orange wastes using the subsequent addition method., 99(17): 8101–8106.

Pham T D, Bui T T, Nguyen V T, van Bui T K, Tran T T, Phan Q C, Pham T D, Hoang T H. 2018. Adsorption of polyelectrolyte onto nanosilica synthesized from rice husk: Characteristics, mechanisms, and application for antibiotic removal., 10(2): 220.

Pham T D, Vu T N, Nguyen H L, Le P H P, Hoang T S. 2020. Adsorptive removal of antibiotic ciprofloxacin from aqueous solution using protein-modified nanosilica., 12(1): 57.

Phuong N T K, Khoi C M, van Sinh N, Chiem N H, Toyota K. 2019. Effects of rice husk biochar and calcium amendment on remediation of saline soil from rice-shrimp cropping system in Vietnamese Mekong delta., 39(2): 1–12.

Phuong N T K, Khoi C M, Ritz K, Linh T B, Minh D D, Duc T A, Van Sinh N, Linh T T, Toyota K. 2020. Influence of rice husk biochar and compost amendments on salt contents and hydraulic properties of soil and rice yield in salt-affected fields., 10(8): 1101.

Pode R. 2016. Potential applications of rice husk ash waste from rice husk biomass power plant., 53: 1468–1485.

Porrang S, Rahemi N, Davaran S, Mahdavi M, Hassanzadeh B. 2021. Preparation andevaluation of mesoporous biogenic silica nanoparticles obtained from rice and wheat husk as a biocompatible carrier for anti-cancer drug delivery., 163: 105866.

Prabha S, Durgalakshmi D, Rajendran S, Lichtfouse E. 2021. Plant-derived silica nanoparticles and composites for biosensors, bioimaging, drug delivery and supercapacitors: A review., 19(2): 1667–1691.

Prabhakaran P, Ranganathan R, Kumar V M, Rajasekar R, Devakumar L, Pal S K. 2017. Review on parameters influencing the rice breakage and rubber roll wear in sheller., 62(3): 1875–1880.

Prapagdee S, Piyatiratitivorakul S, Petsom A. 2016. Physico-chemical activation on rice husk biochar for enhancing of cadmium removal from aqueous solution., 13(1): 27–34.

Prasara-A J, Gheewala S H. 2017. Sustainable utilization of rice husk ash from power plants: A review., 167: 1020–1028.

Puppe D, Leue M, Sommer M, Schaller J, Kaczorek D. 2022. Auto-fluorescence in phytoliths: A mechanistic understanding derived from microscopic and spectroscopic analyses., 10: 915947.

Putranto A W, Abida S H, Sholeh A B, Azfa H T. 2021. The potential of rice husk ash for silica synthesis as a semiconductor material for monocrystalline solar cell: A review.:, 733(1): 012029.

Qu J H, Yuan Y H, Meng Q J, Zhang G S, Deng F X, Wang L, Tao Y E, Jiang Z, Zhang Y. 2020. Simultaneously enhanced removal and stepwise recovery of atrazine and Pb(II) from water using β–cyclodextrin functionalized cellulose: Characterization, adsorptive performance and mechanism exploration., 400: 123142.

Rea R S, Islam M R, Rahman M M, Nath B, Mix K. 2022. Growth, nutrient accumulation, and drought tolerance in crop plants with silicon application: A review., 14(8): 4525.

Rea?o R L. 2020. Assessment of environmental impact and energy performance of rice husk utilization in various biohydrogen production pathways., 299: 122590.