Experimental investigation of the inhibition of deep-sea mining sediment plumes by polyaluminum chloride

Fengpeng Zhng ,Xugung Chen,b, *,Jikng Wei ,Yngyng Zhng ,Weikun Xu ,Ho Li

a College of Engineering,Ocean University of China,Qingdao 266100,China

b Shandong Province Key Laboratory of Ocean Engineering,Ocean University of China,Qingdao 266100,China

c China Merchants Marine and Offshore Research Institute Co.,Ltd.,Shenzhen 518000,China

d National Deep Sea Center,Qingdao 266237,China

Keywords:Deep-sea mining Deep-sea polymetallic nodules Sediment plume Polyaluminum chloride Jet impact Particle flocculation

ABSTRACT Deep-sea sediment disturbance may occur when collecting polymetallic nodules,resulting in the creation of plumes that could have a negative impact on the ecological environment.This study aims to investigate the potential solution of using polyaluminum chloride(PAC)in the water jet.The effects of PAC are examined through a self-designed simulation system for deep-sea polymetallic nodule collection and sediment samples from a potential deep-sea mining area.The experimental results showed that the optimal PAC dose was found to be 0.75 g/L.Compared with the test conditions without the addition of PAC,the presence of PAC leads to a reduction in volume,lower characteristic turbidity,smaller diffusion velocity,and shorter settling time of the plume.This indicates that PAC inhibits the entire development process of the plume.The addition of PAC leads to the flocculation of mm-sized particles,resulting in the formation of cm-sized flocs.The flocculation of particles decreases the rate of erosion on the seabed by around 30%.This reduction in erosion helps to decrease the formation of plumes.Additionally,when the size of suspended particles increases,it reduces the scale at which they diffuse.Furthermore,the settling velocity of flocs (around 10-2 m/s) is much higher that of compared to sediment particles (around 10-5 m/s),which effectively reduces the amount of time the plume remains in suspension.

1.Introduction

The accumulation of greenhouse gases in the atmosphere has resulted in increasingly severe global climate change issues.It is imperative to reduce the amount of CO2in the Earth’s atmosphere[1].There are two approaches to achieving this goal.Firstly,various technological means can be employed to store CO2in suitable formations [2].Secondly,it is crucial to curb CO2emissions.The development of electric vehicles is a step towards achieving this objective[3].This has led to a significant increase in the manufacturing of batteries and semiconductor devices [4],resulting in a strong demand for metals such as nickel,copper,cobalt,and manganese[5].The deep seabed contains a significant amount of polymetallic nodules,which are rich in nickel,copper,cobalt,and manganese [6].Research has indicated that there are approximately 3 trillion tons or more of polymetallic nodules in the deep-sea [7,8].The Clarion-Clipperton Zone (CCZ) alone,a nodule-rich region in the Pacific Ocean,is thought to host resource reserves 5 to 10 times that of terrestrial reserves[9].The potential of deep-sea polymetallic nodules as an unexploited resource for various raw materials has attracted increased global attention[10–12].However,harvesting polymetallic nodules from the seafloor at an industrial scale is a technological and environmental challenge [13].Deep-sea nodules have diameters of 1–20 cm and densities of 1.7–3.0 g/cm3,and they are generally buried in the surface layer of the deep seabed at water depths of 4000–6000 m[14].

The ‘‘track vehicle traveling-jet collecting-pipeline lifting” system has been widely recognized as the most promising technology for deep-sea polymetallic nodule collection[15].The environmental impact of nodule collection is primarily caused by the sediment plumes generated during the collection and tailings discharge process [16],with benthic plumes generated by jet collection being the most damaging [17,18].The resulting sediment plume alters the living environment of benthic organisms,increases the concentration of suspended solids in the water,and affects the chemical properties of the water [19–22].Furthermore,a study conducted on functional,biochemical,and molecular levels confirmed the harmful effects of sediment plumes on biological individuals[23].The United Nations Convention on the Law of the Sea emphasizes the need to safeguard deep-sea biodiversity and protect the marine environment from the potential harm caused by mining activities.To achieve this,the International Seabed Authority,along with countries and organizations involved in deep-sea mineral exploration and development,must prioritize the impact of their activities on the marine ecological environment.Therefore,it is crucial to assess and mitigate potentially damaging sediment plumes generated during the mining of deep-sea polymetallic nodules.

Research on the characteristics and effects of the sediment plumes caused by deep-sea mining has gradually increased,with recent efforts primarily focused on the fate and dispersal of sediment-laden near-bottom plumes formed during nodule collection and the return of excess sedimentary material after nodule separation [24].Rzeznik et al.[25] explored the potential form of deep-sea nodule mining discharge plumes using classic plume theory.This study emphasized the importance of the specific local stratification and vertical shear data in determining the evolution of the plume.Drazen et al.[19] conducted in-situ deep-sea plume experiments at the Tropic Seamount,located 300 nautical miles SSW of the Canary Islands.This study found that factors such as flocculation,background turbidity,and internal tides can reduce the dispersion of benthic sediment plumes and must be taken into account when evaluating the impact and extent of seafloor mining operations.Another study was conducted in the CCZ at 4500 m depth to investigate the dynamics of sediment plumes generated from a deep seabed polymetallic nodule mining pre-prototype collector vehicle[26].The experiments reveal that the excess density of the released sediment-laden water leads to a low-lying,laterally spreading turbidity current.

In the context of deep-sea mining activities,it is possible to significantly minimize the negative impact of a plume on the environment by implementing measures to suppress its generation and spread.However,there is currently limited research on how to effectively suppress the plume that arises during the collection of deep-sea polymetallic nodules.Helmons et al.[27] indicated that there were many similarities in equipment and processes between dredging and deep-sea mining.Experience and best practices from the field of dredging engineering thus might be used to reduce,mitigate,and manage suspended sediment plumes generated by mining equipment.This experience suggests it would be best to design the mining vehicle to be as wide as possible so the collector can move forward more slowly,resulting in more favourable source conditions for the turbidity plume.In addition,optimization of the mining equipment and processes is paramount to reduce the quantity of entrained water and/or sediment,and thus the source of the sediment plume.However,these measures to address the plume may also affect the efficiency of nodule collection.Ali et al.[28] investigated the effects of flocculation on the turbidity current inside a lock exchange,as well as the time scale associated with flocculation.It was shown that flocs are created a few seconds after adding synthetic organic matter in both fresh and saltwater conditions.As a result,the turbidity current settled faster.This also shows that flocculation can be expected when organic matter is present in a saline deep-sea environment.This organic matter is usually composed of organic debris and exopolymers excreted by microorganisms.

Based on the above,this study proposes the addition of polyaluminum chloride(PAC)as a new countermeasure to inhibit the sediment plume caused by jet impact of deep-sea mining operations.This paper aims to study the development and characteristics of sediment plumes produced by jet impact and reveal the effects of PAC on plume generation and evolution.The structure of this paper is as follows.In Section 2,we present our material and experiment.We employed a self-designed deep-sea polymetallic nodule collection simulation system and used deep-sea sediment sampled from a potential mining location to replicate the conditions of deep-sea polymetallic nodule collection.In Section 3,we present a detailed analysis of the development and characteristics of sediment plumes caused by jet impact and the inhibitory effect of PAC on the plume.The mechanism of PAC inhibition on the plume is also discussed and analysed in Section 4.The conclusion of the study is presented in Section 5.

2.Material and experiment

2.1. Experimental system and test instruments

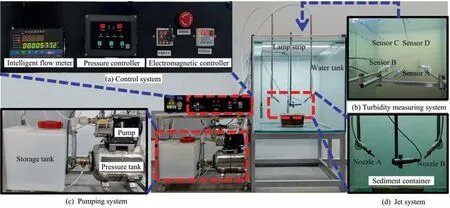

This study employed a self-designed deep-sea polymetallic nodule collection simulation system composed of 4 main components:a control system,a jet system,a turbidity measuring system,and a pumping system,as shown in Fig.1.

Fig.1.The self-designed deep-sea polymetallic nodule collection simulation system.

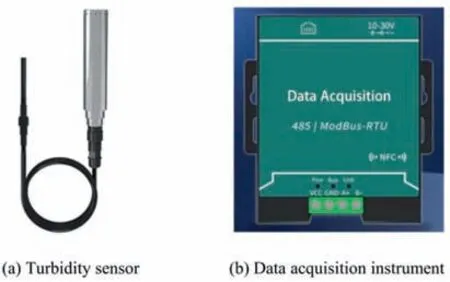

The design diagram of the controlling system,pumping system and jet system is shown in Fig.2.The controlling system was installed at the outlet of a variable frequency pump and consisted of the following instruments (Fig.1a): an electromagnetic controller,used to regulate the duration of the jet with an accuracy of 1 s;an intelligent flow meter,for measuring the rate of jet flow with an accuracy of 0.01 L/h;and a pump pressure controller,which was used to control the pumping pressure with an accuracy of 0.1 MPa.The turbidity measuring system (Figs.1b and 2) was composed of turbidity sensors (Fig.3a),which were used to measure the turbidity of plume with an accuracy of 0.01 NTU,and a data acquisition instrument(Fig.3b),used to upload the data measured by the turbidity sensor to the cloud in real time.The pumping system,illustrated in Fig.1c,was composed of the following instruments: a variable frequency pump designed to generate jet power,with a pressure range of 0–4 MPa and a head of 5 m;a storage tank with a capacity of 40 L,utilized to hold water or a flocculant solution;a 20 L capacity pressure tank,which was connected to the storage tank on one side and the variable frequency pump on the other to help maintain a constant jet pressure and stable jet flow rate.The jet system,illustrated in Fig.1d,was composed of the following instruments: a water tanker of 1 m × 1 m × 1 m and made of highly transparent glass,which served as the main container for conducting experiments;a sediment container of 0.3 m×0.2 m×0.25 m in size,which was used for preparing the test seabed;two jet nozzles with a diameter of 5 mm,used for jet impact;a lamp strip with a length of 1.1 m and a brightness of 1600 lm,mounted to the top of the water tank to facilitate the observation of experimental phenomena;and a connecting pipe,which was used to evenly transfer the water or flocculation solution from the variable frequency pump to the jet nozzle.

Fig.2.The design diagram of the controlling system and jet system.

Fig.3.The turbidity measuring system.

In addition to the aforementioned instruments,connecting rods were utilized to secure the nozzle and turbidity sensors.PAC dosage was measured using graduated cylinders with a capacity of 1000 mL and a stirring bar.The size and shape of the flocs were captured using a macro camera and dispersion dish,and rulers were attached to the water tank to determine the height of plume generation and help calculate diffusion rate.

2.2. Deep-sea sediment and preparation of seabed

The sediment used in the experiment was collected from the deep seabed during the 66th voyage of China Ocean’s ‘‘Deep Sea No.1” scientific research vessel.Sediment samples were collected from the seabed using a visualized gravity piston type multi-tube sampler,following the technical specification GB/T12763.8–2007[29].The obtained sediment samples are columnar in shape,with a height of approximately 40 cm and a diameter of approximately 12 cm.The sampling area,shown in Fig.4,was located in the West Philippine Basin.This basin is situated at the western edge of the Pacific Ocean,bordered by the East China Sea,South China Sea,and the Western Pacific Ocean.It is surrounded by the Philippine Islands,Ryukyu Islands,southern Japan,Mariana Islands.The average water depth of this basin is over 5000 m.The study area is abundant in polymetallic nodule resources[30],making it a highly promising location for metal resource mining.Although the sediment used in this experiment was sourced from a single location in the mining area,previous researches [31,32] indicates that the mineral composition of sediment in different locations within the area is generally similar.This similarity is not expected to significantly affect the test results.

Fig.4.Map of the deep-sea sediment sampling location.

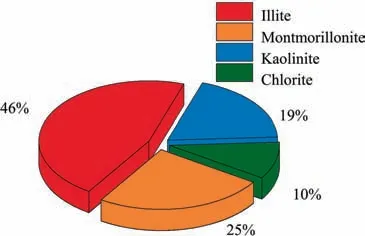

Five sediment tubes were used in this experiment.Table 1 provides the details of their sampling location,water depth,and sampling thickness.This study primarily focuses on analyzing the mineral composition of sticky particles,as flocculation mainly occurs between these particles.A total of 5 sediment samples were collected at 10 cm intervals.The sediment was vacuum freezedried,and 8–10 g of each sample was taken.Deionized water was used to wash away the salt,followed by the addition of 20 mL of 20% H2O2(hydrogen peroxide) to eliminate organic matter.The sample was then centrifuged and washed twice with deionized water.The sediment sample,from which organic matter was removed,was sieved to obtain components with a particle size less than 63 μm.Further extraction of components with a particle size less than 2 μm was carried out using the sedimentation principle.To remove carbonate,1 mol/L hydrochloric acid was added,followed by two washes with deionized water.Finally,components with a particle size less than 2 μm were obtained.Natural slices of clay particle size samples were prepared using the smear method,and X-ray diffraction(XRD)tests were conducted to determine the mineral composition of the sticky particles,as depicted in Fig.5.

Table 1 The basic parameters of the sediment sample.

Fig.5.Composition of the deep-sea sediment.

To ensure success,it is crucial to first prepare the experimental seabed to approximate conditions on the seafloor as closely as possible.To do this,the following steps were taken: 1) the sediment was dried in an oven at 40°C for 72 h until fully dried;2)the dried sediment was soaked in seawater for 72 h and thoroughly stirred to create a slurry;3)the sediment container was prepared by adding layers of gravel (5 cm),sand (5 cm),and geotextile (2.5 cm)from bottom to top,as illustrated in Fig.6;4)the slurry was poured into the upper part of the sediment container to a thickness of 12.5 cm,and then the bottom drain valve was opened,allowing the water to drain and the sediment to consolidate for 12 h;and 5) step 4 was repeated until the surface of the seabed was flush with the top of the sediment container.To minimize sediment usage and replicate real seabed conditions accurately,a layered setting method was employed in step 3.This approach was chosen due to the challenges associated with obtaining deep-sea sediments.Previous studies [33] have indicated that deep-sea mining disturbance is primarily caused by the top 10–15 cm of sediment.Therefore,we placed a 12.5 cm thick layer of deep-sea sediment on the surface.To ensure optimal permeability,a 2.5 cm thick geotextile was installed.Additionally,considering the latest research findings [34] that suggest high strength at the bottom of the deep-sea seabed,we incorporated a 5 cm thick layer of sand and a 5 cm thick layer of gravel at the bottom.

Fig.6.Preparation of the sediment container.

The in-situ sediment characteristics were measured at the seafloor sampling location for comparison with the experimental seabed.Table 2 presents a comparison of the mechanical parameters used in the experimental seabed with those of the in-situ deep seabed,showing how closely the experiment approximates the sediment mechanical properties of the deep-sea study site.

Table 2 Comparison of experimental and in-situ seabed properties.

To accurately replicate the conditions of deep-sea polymetallic nodule collection,the experimental water used was seawater sourced from the East China Sea.Prior to use,the seawater was meticulously filtered to remove any insoluble impurities.Table 3 shows a comparison of the seawater parameters used in the experiment with those of the in-situ seawater (at 5600 m depth).The results indicate that both types of seawater exhibit similar characteristics,thereby ensuring the accuracy and precision of the experiment.

Table 3 Comparison of experimental and in-situ seawater properties.

2.3. The flocculant: PAC

PAC is a novel inorganic polymer flocculant with a chemical formula of[Al2(OH)nCl6–n]m.Here,nrepresents the degree of neutrality of PAC,whilemrepresents the degree of polymerization.PAC exhibits a remarkable bridging effect and high degree of neutralization of colloids and particles in water,resulting in the ability to efficiently remove micro-toxic substances and heavy metal ions.Moreover,PAC’s stable properties make it a promising candidate for water treatment applications,and it is extensively employed in the purification of drinking water.This study utilizes PAC with an effective content of 30%,which is expected to have a high adsorption capacity,noticeable flocculation,and rapid sedimentation velocity [35].To prepare the PAC for use,it is diluted with water at a mass fraction ω of 1:20 to form a solution.

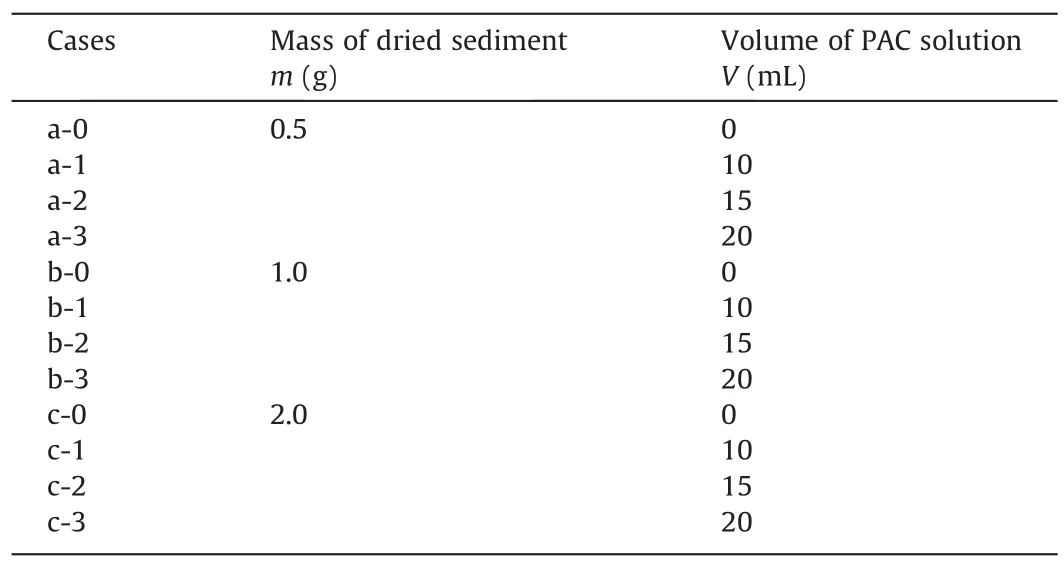

The optimal dosagenvaries depending on the use scenario.Therefore,it is crucial to determinenbeforehand to effectively address the deep-sea sediment plume.In this study,nwas determined through the following steps: 1) dried deep-sea sediments of varying massesmwere placed in measuring cylinders with the turbidity sensor fixed in the middle of the cylinder,and the sediment was then soaked in 1000 mL of seawater for 12 h to ensure complete dispersion;2) a stirring bar was used to form a uniform slurry;3) different volumes of PAC solutions with ω=1:20 were then added to the measuring cylinders;and 4)the change of water turbidityTwas observed,and the PAC dosage at whichTfirst decreased to 10 NTU was chosen as the optimal dosage.The test cases used for determining the optimal dosage of PAC are shown in Table 4.

Table 4 Test cases for determining the optimal dosage of PAC.

2.4. Experimental setup and procedures

The following experimental procedure below was conducted for each set of conditions:

(1) The experimental instruments were thoroughly cleaned to prevent the introduction of external impurities.

(2) The sediment container,which had been prepared according to the process outlined in Section 2.2,was positioned in the centre of the water tank,which was then filled with seawater.

(3) The storage tank was filled with either seawater or PAC solution with the experimental dosage determined in Section 2.3.

(4) The jet nozzles were moved away from the sediment container and the control system was adjusted to remove internal air from the jet system and ensure that the jets from Nozzle A and Nozzle B were uniform and synchronized.

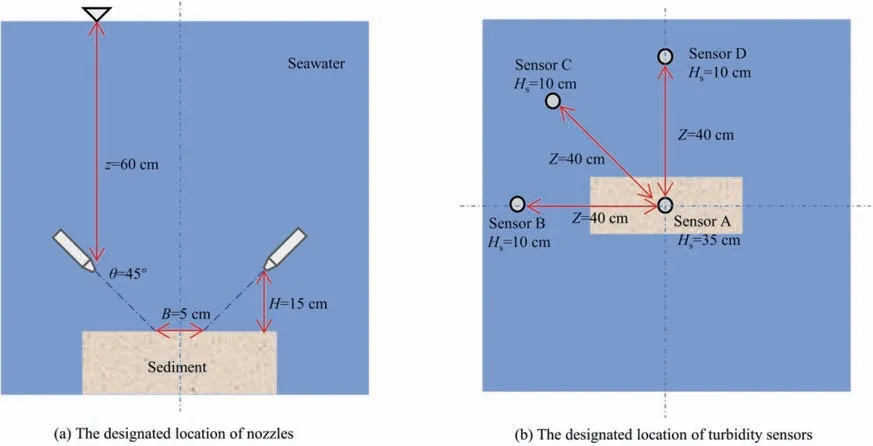

(5) The adjusted nozzles were then positioned on the upper section of the sediment container,with a heightHof 0.15 m from the seabed surface,an incident angle θ of 45°,and a target separation distanceBof 5 cm between the two jet impact points,as shown in Fig.7a.

Fig.7.The designated location of nozzles and turbidity sensors.

(6) Turbidity sensors were positioned at their designated locations (Fig.7b),with Sensor A positioned to measure the immediate turbidity during plume generation,and Sensors B,C,and D set to monitor the turbidity changes during the diffusion and sedimentation process of the plume.

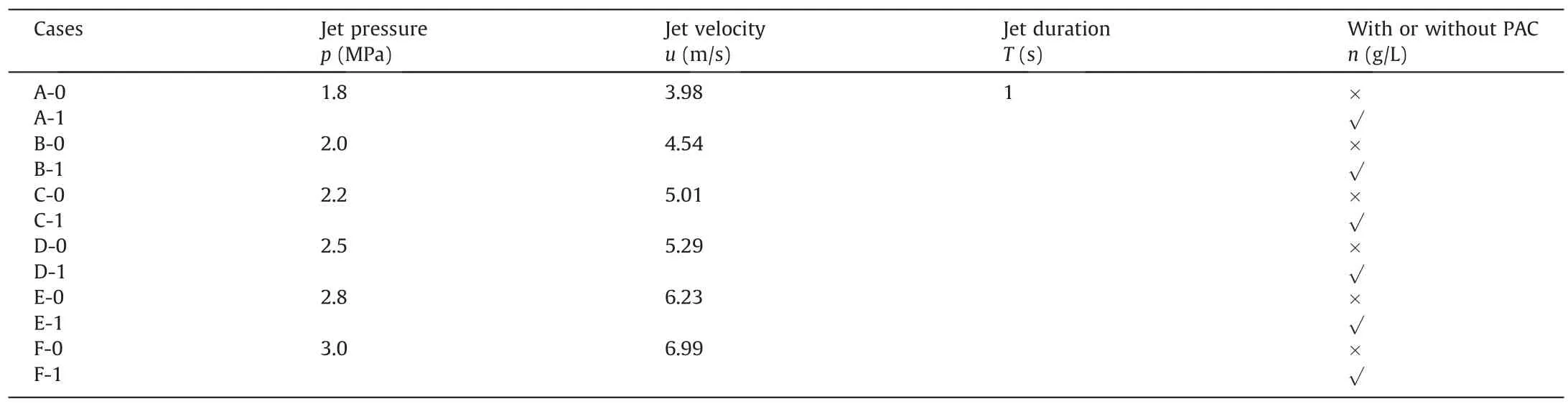

(7) The light strip was turned on,the pump pressure controller was used to adjust the pressure of the water pump to set different jet flow rates,and the electromagnetic controller was used to set the jet duration for the given set of test conditions,as shown in Table 5.

Table 5 The test cases and corresponding conditions.

(8) The turbidity measuring system was used to measure plume turbidity in real time,and the plume height and diffusion rate were observed.

(9) To determine the size and shape of floc,different locations within the plume were sampled using an extended straw that minimizes disturbance.

Because this study focuses on utilizing PAC to inhibit sediment plumes caused by deep-sea mining,the experimental conditions aim to replicate the actual conditions of deep-sea polymetallic collection as accurately as possible.The jet parameters in Steps (5)and (7) were also set based on this principle [36].

3.Results

3.1. The optimal dosage of PAC

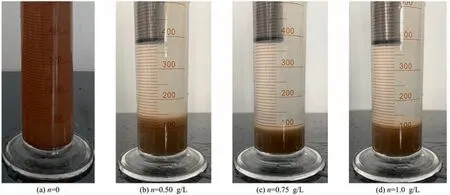

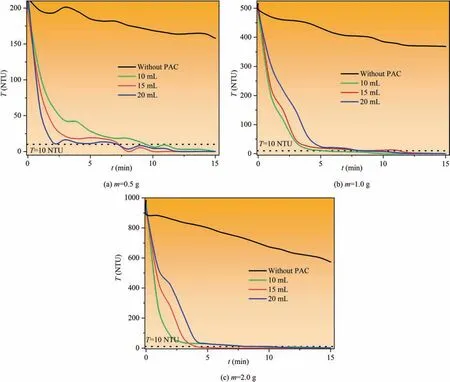

As described in Section 2.3,a series of experiments were conducted to explore the optimal dosage of PAC for this study.Fig.8 illustrates the effect of PAC on reducing turbidity form=2.0 g att=5 min,and Fig.9 shows plots of the temporal evolution ofTfor different sediment masses and PAC solutions.

Fig.8.The effect of PAC dosage on plume turbidity for m=2.0 g at t=5 min.

Fig.9.Plot of T vs.t for different conditions.

According to the findings presented in Figs.8 and 9,the addition of PAC is effective at reducing sediment plumes.This is due to the fact that PAC can improve flocculation between particles in the plume,ultimately leading to more rapid sedimentation.In various test conditions,the turbidity of the plume can be rapidly reduced by 10,15,and 20 mL of PAC.However,according to Fig.9,the performance of 15 mL PAC exhibits greater stability.Hence,we have chosen the optimal dose of PAC to be 15 mL.Based on these findings,we have chosen an optimal PAC dosage ofn=0.75 g/L through Eq.(1),whereVwis the total volume of water.

In the conventional water treatment industry,PAC solution is typically added to the turbid liquid to be treated and stirred to evenly distribute and achieve desired levels of impurity removal.However,in this study,we took into account the unique operational mode of deep-sea polymetallic mining,and instead propose adding PAC directly to the jet water in order to suppress the resulting sediment plume without interfering with the mining of polymetallic nodules.

3.2. Sediment plume development and characteristics

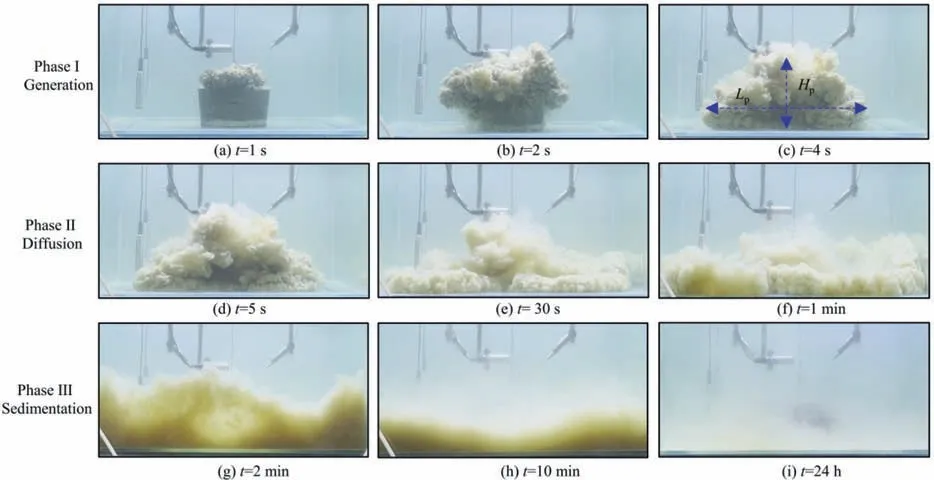

The development and characteristics of sediment plumes produced by jet impact in the absence of PAC can be determined from the results of test cases A-0,B-0,C-0,D-0,E-0,and F-0.For instance,the progression of plume development for test case D-0 is illustrated in Fig.10.This progression can be divided into three phases: generation (Phase Ⅰ),diffusion (Phase Ⅱ),and sedimentation (Phase Ⅲ).The variations in turbidity during different phases are shown in Fig.11.The measurements obtained from Sensors B,C,and D were found to be consistent,indicating that the plume’s diffusion was uniform in space.The turbidity curves shown in Fig.11b and c were generated by averaging the measurements obtained from these three sensors.Based on experimental observations,it was found that the plumes in all test conditions can diffuse to Sensors B,C,and D within 5 s.Therefore,the starting time of thex-axis in Fig.11b is set att=5 s.

Fig.10.The progression of plume development for test case D-0 (u=5.29 m/s).

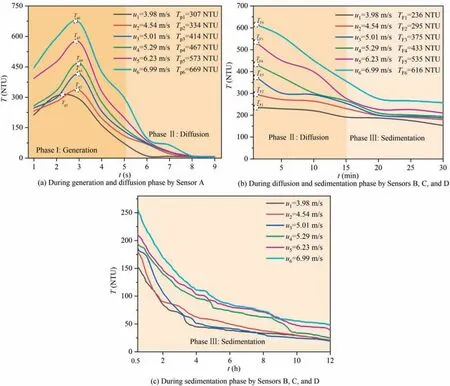

Fig.11.The variations of T during different phases.

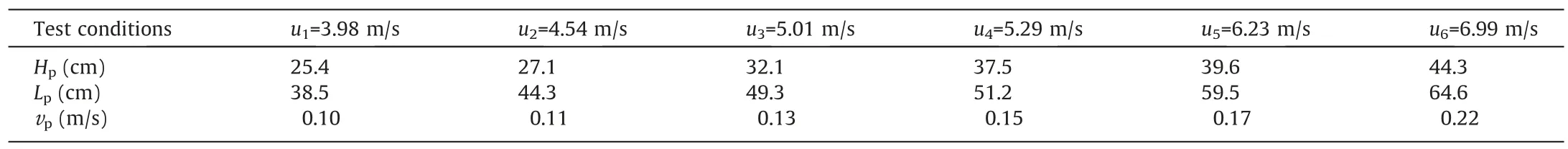

As shown in Figs.10a–c and 11a,during the generation phase,the jet impact dislodged the sediment,creating a plume above the seabed.The plume’s volume rapidly expanded and reached its maximum size within a few seconds.Table 6 provides the size of the plume at its maximum volume for various cases.In Tables 6 and 7,Hpis the height of the plume at its maximum volume,andLpis the width of the plume at its maximum volume.Plume turbidity initially increased slightly and then decreased,with the maximum turbidity being referred to as the primary turbidityTpof the plume.The results of the test indicate that as the velocity of the jet increased,bothTpand the maximum volume of the plume also increased.

Table 6 The maximum dimensions and diffusion velocity of the plume without PAC.

During the diffusion phase,the plume ceased to develop in the vertical direction once it reached its maximum volume(Figs.10d–f,and 11b).Instead,it spread to the surrounding area due to the effects of gravity and turbulence.Within approximately 1–2 min,the frontal surface of the plume would reach the side wall of the water tank.The velocity of the plume’s frontal surface during this phase is known as its diffusion velocity vp,as displayed in Table 6.After 10–15 min of plume generation,the plume flow became less apparent and transitioned into the particle sedimentation phase.As this phase progressed,the turbidity measured by Sensor A gradually decreased until reaching zero.The turbidity of the plume’s frontal surfaceTF,measured by Sensors B,C,and D,gradually decreased during the diffusion phase.The results indicate that there is a proportional relationship between vpandu,as well as betweenTFandu.Additionally,TFwas found to be slightly smaller thanTpin each test case.

Particle sedimentation occurred during the plume generation and diffusion phases,but it is affected by turbulence and the impact is not very significant.Therefore,this study focuses on the sedimentation phase that occurs after the plume diffusion phase.As shown in Figs.10g–i and 11c,the turbidity of the plume decreased rapidly at first,followed by a more gradual decline.The sedimentation phase of the plume was extremely long,with sediments still suspended in the bottom 10 cm of water after 24 h.This long residence time highlights the potential harm of the plume to the environment.

3.3. The inhibitory effect of PAC on plumes

The inhibitory effect of PAC on sediment plumes can be demonstrated by comparing the results of test cases using PAC (i.e.,A-1,B-1,C-1,D-1,E-1,and F-1)with those without(i.e.,*-0).The effects of PAC can be observed in all three phases of plume generation,diffusion,and sedimentation,as shown in Fig.12.Also shown are comparisons of the correspondingTvariations during the plume generation stage (Fig.13) and diffusion and sedimentation phases(Fig.14) both with and without PAC addition.Table 7 gives the dimensions of the plume at its maximum volume as well as its diffusion velocity vpfor test cases with PAC.

Table 7 The maximum dimensions and diffusion velocity of the plume with PAC.

Fig.12.The inhibitory effect of PAC on the plume for test case D-0 (u=5.29 m/s).

Fig.13.Comparison of T variations during plume generation with and without PAC addition.

Based on Fig.12a,d and Table 7,the maximum plume volume generated in test cases with PAC was much smaller than in those without PAC.According to Fig.13,it was also found thatTpwas slightly greater and occurred earlier with PAC than without.The addition of PAC also led to a more rapid decrease in turbidity.These observations can be explained by PAC causing the suspended sediment particles to undergo coagulation during plume generation,which leads to an increase in dispersed flocs in the water and a short-term rise in water turbidity.Over time,particles aggregate and develop into larger flocs through flocculation,which causes their suspension rate under the hydraulic turbulence of the jet to decrease,resulting in a smaller plume volume compared to test cases where PAC was not added.The settling velocity of flocs is much faster than that of suspended sediment particles,leading to a rapid decrease in turbidity.As a result,they have mostly settled out during the plume diffusion phase.In addition,TFwas significantly lower in experiment runs with PAC than without(Figs.12b,e and 13).As given in Table 7,plumes with PAC also appeared to have a smaller vp.The use of PAC resulted in a significant reduction in turbidity within 10 min and a considerably shorter sedimentation phase.As illustrated in Fig.12c and f,a thick layer of suspended particles remained long after the test run without PAC,still 10 cm thick after 12 h.In contrast,the addition of PAC led to a more rapid settling of suspended particles,forming a 0.5 cm-thick sedimentary layer within 5 min.

3.4. Flocculation of sediment particles subjected to PAC

As discussed in Section 3.2,PAC has an inhibitory effect on the plume.This is because PAC causes sediment particles to flocculate,forming flocs that alter the generation,diffusion,and sedimentation characteristics of plumes.To examine this process,water samples were periodically collected from the experimental plumes using a long-necked straw and transferred to a dispersion dish.The size and shape of the particles or flocs were then captured using a macro camera,as depicted in Fig.15.

Fig.15.The size and shape of particles or flocs for D-0 (without PAC) and D-1 (with PAC).

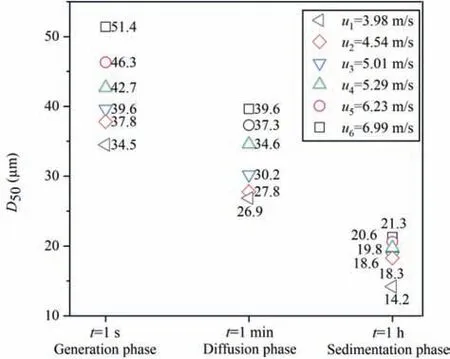

The particles suspended in the water during plume generation without PAC are depicted in Fig.15a.As the suspended particles were very small (micrometre scale),determining the particle size directly through the captured images was challenging.Therefore,we used a laser particle size analyser to measure the particle size at different plume development phases in the experiment runs without PAC.The results,presented in Fig.16,show that the median particle sizeD50decreases gradually as the plume evolves through the phases of generation,diffusion,and sedimentation.This can be attributed to the gradual sedimentation of larger particles over time.Furthermore,theD50of suspended particles during generation and diffusion increases withu.The stronger jet causes a greater disturbance,resulting in a higher concentration of suspended particles and the formation of larger flocs.

Fig.16.D50 for different plume development phases without PAC.

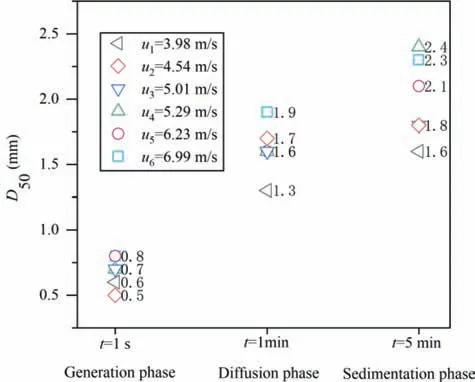

In the presence of PAC,the suspended particles set to form flocs during the plume generation phase,as shown in Fig.15b.These flocs are larger in size (millimetre scale) compared to the suspended particles in Fig.15a,but have a looser structure.These experimental phenomena provide an explanation for the higher value ofTpin test cases with PAC,as compared to those without PAC.Fig.15c shows the evolution of suspended particles from coagulation to flocculation,with increasingly compact floc structures.With continued flocculation,the flocs gradually increase in size and can reach centimetre scale during the plume settling stage,as depicted in Fig.15d.

The particle sizeDof flocs in both horizontal and vertical directions (DxandDy) can be determined by analysing the figures.Eq.(2) can be used to obtain floc size in different plume development stages,as shown in Fig.17.

Fig.17.D50 for different plume development phases with PAC.

The results depicted in Fig.17 demonstrate that floc size increases gradually with the development of the plume in test cases with PAC.With PAC,theD50of floc in the plume was found to be significantly larger,which is attributed to the fact that PAC promotes particle flocculation.At each phase of plume development,theD50of floc increases with increasingu.This is due to increased sediment disturbance from the jet,which results in higher concentrations of suspended particles and more sediment involved in flocculation,ultimately leading to the formation of larger flocs.

4.Analysis and discussion

PAC can efficiently inhibit the generation-diffusion-sedimenta tion of sediment plumes,as described in Section 3.The‘‘generation-diffusion-sedimentation” of a plume is essentially the ‘‘suspension-transportation-deposition” of sediment particles due to turbulent flow caused by jet impact,and the addition of PAC enhances the scouring resistance of particles when exposed to turbulence.Therefore,this study aims to assess PAC’s inhibitory effect by considering two factors:the turbulence characteristics of the plume and the scouring resistance of the particles.

The turbulent behaviour of a plume varies significantly depending on the source conditions,which can be characterised by a few key parameters.The Richardson numberRirepresents the relative importance of natural convection,driven by the density differences,and forced convection,driven by the source momentum flux,which can be expressed as Eq.(3) [37],

whereg'=denotes the reduced gravity (or buoyancy) of a plume fluid with density ρsin an ambient fluid density ρa;bthe characteristic length parameter (here the radius of the plume);andWthe characteristic vertical velocity.ForRi<<1,momentum dominates,which is known as a ‘‘forced” plume regime,whereasRi>>1 implies either a very large buoyancy or plume radius for the given velocity and is called a ‘‘lazy” plume [25,38] For deepsea mining sediment plumes,Ri<<1 and thus they are considered as forced plumes.

Scouring resistance is defined as the ability of particles in the seabed to resist suspension,dispersion,and flushing away due to hydrodynamic forces.The scouring resistance forceFsRof plume particles can be expressed as a function of the parameters shown in Eq.(4) [39],

whereKis the particle shape factor;ρ the density of the particles;andcparticle cohesion.In the following sections,we examine the mechanisms by which PAC inhibits plume generation,diffusion,and sedimentation using the theories of forced plume and scouring resistance.

4.1. Mechanism of plume inhibition by PAC during the generation phase

The generation of plumes due to jet impact is primarily caused by the erosion of soft cohesive sediment beds induced by shear flow.The sediment erosion rateEis the key factor that affects the volume of the plume generated,which can be expressed as Eq.(5) [40],

where τbis the shear stress;τcrthe critical shear stress of sediment;ME=the erosion parameter,in whichcv the consolidation coefficient;Φsthe solid’s volume concentration;ρdrythe dry density of seabed;andcuthe undrained shear strength of seabed.

As the seabed preparation process remained consistent throughout the study,the seabed characteristics (τcr,cv,and ρdry)should be similar for all tests.The density of the jet liquid is the main factor affecting τb,along withu,B,H,θ,andz.The addition of PAC did not significantly alter the density of the jet liquid in this experiment.Instead,PAC primarily modifies ΦsandD50for a givenu.The value of Φscan be determined by using the values ofTpdetermined in Section 3.2,since Φs=αTis applicable for turbid liquids that contain a calcium or silicon suspension with low suspension concentration (where α is a coefficient).As stated in Section 3.3,PAC combines with sediment particles in the plume generation phase,resulting in the formation of larger flocs.For Eq.(5),D50represents the median particle diameter when the shear flow is in contact with the seabed.For the test conditions without PAC,the value ofD50is determined as(see Section 3.3,Fig.16).However,when PAC was added during testing,the particles would set upon contact,causing particle size to increase rapidly.Therefore,for PAC tests,D50=β is a reduction factor with a value of 0.1,withas shown in Fig.17.Finally,Ecan be calculated for different conditions as shown in Table 8.It should be noted thatE0denotes the sediment erosion rate for the test conditions without PAC,E1the sediment erosion rate for the test conditions with PAC,andRthe reduction ofEsubjected to addition of PAC.

Table 8 E and R for different conditions.

According to the results,the addition of PAC can reduceEby approximately 30% for a givenu.This can be attributed to the fact that PAC significantly increasesD50.It is important to note thatEis a parameter that characterizes the amount of plume generation,and although it may be related to plume volume,further research is needed to establish the exact relationship between the two variables.

4.2.Mechanism of plume inhibition by PAC during the diffusion phase

In order to characterize the diffusion ability of a plume during its diffusion phase,Woods proposed a characteristic length scale(L) based on a forced plume,given by Eq.(6) [41].

whereB0=g'kQis the initial buoyancy flux,in whichka coefficient andQthe volume flux exiting from the discharge;andaa key parameter called the entrainment coefficient,which expresses the interaction between the plume and the ambient fluid and controls the plume dynamics,and it can be expressed as Eq.(7):

whereajis the jet entrainment coefficient,taken to be 0.057;applume entrainment coefficient,with a value of 0.088;andAthe Atwood number,which can be expressed as Eq.(8).

where ρs=ρa+Φs,and Φs=αTF,withTFvalues derived from the test results for each set of conditions,as shown in Fig.14.Thus,Acan be expressed as Eq.(9).

Based on Eqs.(7)–(9),it was found that for a givenu,the addition of PAC resulted in a smaller value ofbandTF,leading to a largera.According to Eq.(6),when>1,the value ofLdecreases with an increase ina.Therefore,under the same jet conditions,the addition of PAC increasesa,which in turn reducesLand decreases the plume diffusion rate.

4.3. Mechanism of plume inhibition by PAC during the sedimentation phase

During the sedimentation phase,the turbulence caused by the jet impact dissipates,and the turbidity of the plume is directly influenced by the settling velocity ω of particles in static water.The focus of this section is to analyse the particle settling velocity under different test conditions and assess the corresponding impact of PAC.

In the absence of PAC,the flocculation of clay particles is relatively weak,and the settling velocity of particle,denoted by ωc,can be determined using Eq.(10) [42],

wheredis the particle size,here assumed to be(Fig.16);μ the dynamic viscosity of water(1.3×10-3N·s/m2);ρpthe density of particles in their dispersed state (1.30×103kg/m3);andKthe coefficient of 3.The theoretical settling velocity of the particle in the absence of PAC can thus be determined.

Cohesive particles can bond with adjacent particles through flocculation to form flocs with larger particle sizes [43].Eq.(11)is widely used to determine the settling velocity ωfof a floc [44].

where α and β are shape factors(the flocs are assumed to be spheres in this study,so α=β=1);dthe diameter of the particles in their dispersed state,taken to be(Fig.16);Dthe diameter of floc,which is taken asfrom Fig.17;Nfthe fractal dimension of the floc,assumed to be 3 for a globular particle[45];andRe*Reynolds numberRe*=The theoretical settling velocity of a floc can thus be determined.

For greater accuracy,we opted to use the particle size measured in the plume diffusion phase to calculate ωcand ωf,rather than in the sedimentation phase.This allowed us to determine the particle settling velocity more precisely.The calculation results for particle settling velocity are shown in Table 9.

Table 9 Calculated values of ωc and ωf for each set of experiment conditions.

The results indicate that the addition of PAC causes the particles to flocculate and form larger flocs,resulting in a significantly higher settling velocity compared to sediment particles.This is consistent with experimental observations during the plume sedimentation phase.

In summary,Fig.18 illustrates the underlying mechanisms by which PAC inhibits sediment plumes throughout their entire development process.PAC causes particle coagulation during the plume generation phase,which inhibits the erosion of shear flow on sediments and reduces particle suspension.During the plume diffusion phase,PAC reduces the entrainment capacity of the plume and limits particle transport.During the sedimentation phase,PAC intensifies the flocculation process of particles,resulting in the formation of larger flocs and ultimately accelerating the settling of suspended solids.

Fig.18.The underlying mechanisms by which PAC inhibits sediment plumes.

5.Conclusions

This study proposes the addition of PAC to the jet water to help mitigate sediment plumes generated during the collection of deepsea polymetallic nodules.A series of experiments were conducted using sediment sampled from a prospective mining area and a custom deep-sea polymetallic nodule collection simulation system to investigate the effects of PAC on sediment plumes.The resulting plume inhibition was analysed using a forced plume model and particle scouring resistance theory.The main conclusions are as follows.

(1) The optimal PAC dosage for plume control is not influenced by the sediment content in the plume,but rather by the PAC content when diluted in seawater.In this experiment,the optimal PAC dosage was found to be 0.75 g/L.

(2) The progression of plume development can be divided into three phases: generation (Phase Ⅰ),diffusion (Phase Ⅱ),and sedimentation (Phase Ⅲ).During the generation phase,the turbidity of the plume initially increased slightly and then decreased.During the diffusion and sedimentation phases,the turbidity gradually decreased,with a very prolonged sedimentation phase.

(3) By comparing the plume’s volume,characteristic turbidity,diffusion velocity,particle size and settlement time with and without PAC,it was observed that the addition of PAC significantly inhibited the plume’s entire development process.

(4) PAC causes particle coagulation during the plume generation phase,which inhibits the erosion of sediments due to shear flow,thereby reducing particle suspension.During the plume diffusion phase,PAC reduces the entrainment capacity of the plume and limits particle transport.During the sedimentation phase,PAC intensifies the flocculation process of particles,resulting in the formation of larger flocs and ultimately accelerating the settling of suspended solids.

The research is conducted in a laboratory setting using simulated conditions,which may not fully reflect the complex and dynamic nature of deep-sea mining operations in the real world.Further validation of the findings in real-world conditions is needed to confirm their applicability.This study has several limitations.In future research,we will focus on using numerical simulation to verify the conclusions drawn from this study.Specifically,we will investigate the impact of pH,pressure,temperature,and organic matter content on deep-sea particle flocculation.Furthermore,we will explore the effects of boundary conditions on plume diffusion,examine the application of PAC in deep-sea environments with respect to biological activity,and study the mechanism of floc fragmentation and degradation in deep-sea environments.

Acknowledgments

This work was supported by the National Natural Science Foundation of China(Nos.52225107,U2106224,U1906234,51822904,and U1706223)and the Fundamental Research Funds for the Central Universities(No.202041004).The authors gratefully acknowledge the 66th voyage of China Ocean’s ‘‘Deep Sea No.1” scientific research vessel for providing the deep-sea sediment samples used in this study.

- 礦業科學技術學報的其它文章

- Preliminary research and scheme design of deep underground in situ geo-information detection experiment for Geology in Time

- Numerical and experimental investigation on hydraulic-electric rock fragmentation of heterogeneous granite

- Heat transfer and temperature evolution in underground mininginduced overburden fracture and ground fissures:Optimal time window of UAV infrared monitoring

- Classifying rockburst with confidence: A novel conformal prediction approach

- Drilling-based measuring method for the c-φ parameter of rock and its field application

- Pore-pressure and stress-coupled creep behavior in deep coal: Insights from real-time NMR analysis